Extreme weather, cyber attacks, volatile supply chains, trade disputes, war: Oil and gas fleets face pressures from all sides. Accenture reports that 82% of oil and gas fleets are experiencing moderate to severe supply chain disruptions, which can add $10 to $15 per barrel to the breakeven cost of a new well.

That’s why oil and gas fleets need to do everything they can to insulate themselves from disruptions and volatile energy prices.

While you can’t control the weather or the geopolitical landscape, you can take steps to reduce your fleet’s downtime, and thus increase overall productivity.

Many oil and gas fleets operate across giant geographical ranges, so it’s hard to know exactly how well your fleet is performing. If something breaks on a remote site hundreds of miles from headquarters, it could take days to bring equipment back online. And if an essential part is stuck in supply chain limbo, it could be weeks.

All that downtime adds up to lost productivity that hurts your bottom line.

However, a fleet management solution gives you insights that can help you reduce downtime so you can increase productivity.

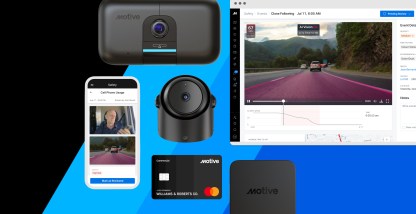

Motive’s fleet management solution can help you:

- Gain visibility into your equipment, assets, and utilization trends.

- Shift to predictive maintenance.

- Improve asset utilization.

Gain visibility across your entire oil and gas fleet

Do you know where all your equipment and assets currently are? Which are idle, and which are active? Which are on schedule, and which might be running late?

Motive’s GPS and geofencing give you real-time insights into the current location of your drivers, assets, and equipment. With that information, you can track oil and gas fleet arrivals and departures. You can even set up geofences that alert you when equipment enters or exits a site, so you can proactively notify your customers with an accurate expected arrival time. That simple heads-up can ensure that the site or contractor is ready, minimizing your own driver’s wait time.

Chad Goodrich, Service Administrator for Equipment Corporation of America, says, “Motive has changed the way we work. Now we can see all our drivers, vehicles, and equipment, in one place — saving us time from checking files or multiple calls.”

Beyond helping your own operations, you can also share this visibility with your customers or other teams on a worksite.

Allen Chatten of Cordy Environmental did just that through the Motive Fleet Management Dashboard. “I showed the customer how to use geofence and [telematics] on all of our trucks, so she could do a query on her own,” he says. “The fact that we were able to teach our customer how to do this, well, that just raised our accountability.”

Read: How AI can improve oil and gas fleet sustainability.

Shift to predictive maintenance

Reacting to sudden breakdowns in your oil and gas fleet is disruptive and expensive. Your driver and equipment may wind up stranded, waiting for assistance while your delivery grows later and your customer gets frustrated. You might even face penalties.

Unplanned maintenance is expensive, as you’re at the mercy of a local shop rather than your own facility. Plus, with today’s supply chain issues, you may be out of luck while you wait for essential parts. The costs of unplanned maintenance grew by 3% in 2021, and between technician shortages and inflation, they’re likely growing even faster today..

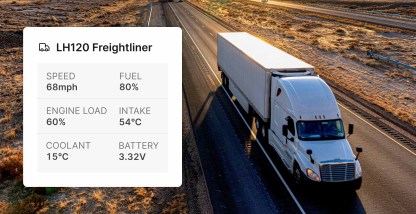

While traditional maintenance schedules are based on elapsed time, Motive can help you shift to predictive maintenance based on your vehicle’s actual condition and usage. Predictive maintenance combines sensor data about vibrations, temperature, pressure, and noise to detect early warning signs of malfunction. Motive can alert you to diagnostic fault codes as they occur, so you can act quickly before the problem escalates.

Motive also gives your fleet managers detailed vehicle utilization reports that can identify irregular fuel consumption or other anomalies that may warn of looming issues.

Overall, shifting to preventive maintenance helps fleets reduce maintenance-related downtime by about 20%.

Improve oil and gas asset utilization

Knowing where your assets are can improve overall utilization by reducing detention times and improving efficiency.

Motive Fleet View gives your dispatchers real-time location tracking that can help them find the nearest driver, share documents, and message drivers. Together, this speeds up just-in-time deliveries while helping to provide an accurate ETA to the worksite supervisor or customer. With everything in the Motive app, your driver and the site are ready. Dispatchers can even see a driver’s HOS status right in the Motive Driver App, so they won’t dispatch a driver who is approaching their limit.

Mohawk Materials’ previous fleet management solution only updated equipment locations every 30 minutes. Since switching to Motive, Mohawk’s managers can now track inbound vehicles to ensure the outbound load is ready to go.

Wes Beck, logistics coordinator at Mohawk, explains, “Before, my plant managers would have to call to ask where the truck is and would have to wait 30 minutes for the next refresh to give an update. Now they don’t have to call me at all. They can check right on their phones and find out in seconds.”

Real-time visibility has cut asset downtime for Mohawk, saving them thousands of dollars per year by increasing efficiency and customer satisfaction.

Jayson Boydstun, CFO of Flying Star Transport, points to significant productivity gains. “Motive’s geofencing and detention time reports helped us realize a 10% to 15% improvement on our efficiencies, measured by hours per load,” he reports. “We’ve gone from roughly five hours per load last year on a 130-mile haul, and now we’re running about four hours per load on a 120-mile haul. We gain so much when we can move faster.”

Flying Star is also using Motive’s insights to examine metrics like average wait times and inspire conversations about efficiency with customers and drivers.

See how your oil and gas fleet can benefit from Motive

Want to learn how Motive can help cut your oil and gas fleet’s downtime and improve productivity? Request a demo to get started.