Experts discuss implementing sustainable operations at Vision 24.

Key takeaways:

- With greater visibility into physical operations, companies can measure their impact and pinpoint areas to reduce consumption and waste that benefits both their bottom line and their sustainability efforts

- By using data to surface areas where operators can be more efficient, companies can be more profitable, reduce their costs, and reduce their environmental impact.

- The transition to zero-emission vehicles (ZEVs) is a road filled with complexities and economic decisions, but there are tools and levers (like Motive’s data analytics and fleet management services, Navistar’s consulting programs, and Revoy’s managed electrification solutions) to help make a smooth transition

- Companies should be planning now and investing in the future where they can, as the market and regulatory pressures will demand sustainability measures, planning and lead times may be long-term projects, and getting ahead can give you a competitive advantage

At Vision 24, Chief Product Officer Jai Rangananthan and I hosted a fireside chat and panel discussion about sustainable operations in the physical economy, focusing on the pressures for companies to improve their environmental sustainability, the realities and practical hurdles of becoming more sustainable, and what companies can and should be doing now to improve their operations and plan for the future.

We organized this session to give our customers realistic, actionable insights and spur discussion and problem-solving at their organizations and amongst their peers. To inform and provoke genuine conversation around the realities of implementing sustainable operations, Motive put together an all-star, representative group of industry experts, including Motive customers, OEMs, and policy analysts to talk about these realities, without sugarcoating. The panel included:

- Jeff Gorestki, the VP of Logistics for CRH Americas

- Paul Ruiz, the Director of Energy and Environment Policy at the American Trucking Associations (ATA)

- Stefan Sahlmann, Vice President EV Solutions Development & Activation at Navistar

- Ian Rust, CEO of Revoy

- Jai Ranganathan, Motive’s Chief Product Officer

These panelists each gave insights from their perspectives on hot-button topics like:

- The regulatory and market pressures, such as EPA’s GHG Phase 3 Regulations, California’s Advance Clean Fleets initiatives, and pressures from customers and the public

- The economic realities of implementing sustainability measures

- The reasons, and advantages of, taking steps now to improve a company’s sustainability

Here’s a video of the panel, in full, but please read on below for a brief summary of the panel and more information and insights from our panelists.

Panel Highlights

Jeff Goretski of CRH Americas, an organization whose sustainability initiatives have been in full swing, partially as a result of being part of a European organization with aggressive net-zero goals and targets, discussed how CRH sees opportunities not only to reduce costs by being more efficient and reducing waste in their current operations, but also to create competitive and economic advantages by piloting, testing, and learning how to provide the sustainable operations that customers and regulators will be looking for tomorrow.

Being ahead of the curve on ZEVs and low-carbon technology implementation allows CRH to understand where the total cost of ownership and return on investment works best while also sorting out the logistics and infrastructure of implementing new technologies into their operations, setting them up for a more cost-effective, streamlined future.

While this strategy requires some upfront investment, CRH knows it sets them up for long-term, sustainable operations, which gives them an advantage, especially as implementation costs come down. Making investments today also gives CRH a leg up on the competition by providing sustainable offerings, while also making upscaling sustainable operations easier and more economical. CRH also invests heavily in funding innovation, seeking grants and incentives, and other programs and strategies to help sustainability make economic sense, knowing that these investments pay dividends down the road.

CRH also focuses on reducing waste and being more efficient within their current operations because it reduces their footprint while saving money. Jeff noted that often by simply creating visibility around energy/fuel consumption and benchmarking across their organization, operations managers inherently track and manage their performance to find ways to be more efficient, consume less, and reduce emissions while saving the organization money. As they say, what gets measured gets managed.

Paul Ruiz of the ATA weighed in from a trucking policy perspective, noting first that people should be optimistic about how both the trucking industry and OEMs have come a long way in making transportation more energy efficient. He discussed the carrots (i.e., customers willing to pay a premium and governments offering grants and incentives, such as those available from the IIJA) and sticks (i.e., regulatory requirements) driving change in the trucking industry. He reflected thoughtfully and critically on the realities of meeting certain regulatory goals and targets. Moving to ZEVs in the commercial vehicle space is truly a three-pronged issue. It requires utilities and infrastructure, manufacturing and materials availability for ZEV technologies, and the economic realities and total cost of ownership placed on transportation companies to all interact in lock-step in a short time frame to make the changes and upgrades necessary to have a zero-emission trucking sector. These upgrades come at a high shared cost, as a recently released report set infrastructure upgrades alone at around $1 trillion.

Paul urged the consideration of emission-reduction technologies other than battery-electric vehicles (BEVs) to make improvements more readily accessible and realistically implementable. He emphasized the importance of everything working in tandem on a realistic timeframe to ensure that companies have a good experience with ZEV implementation from a logistics, infrastructure, and total cost of ownership perspective. If companies invest in new technologies that are difficult to utilize, it could create friction and hesitancy in ZEV adoption. If companies are going to make heavy upfront investments, they need to have a smooth and economically efficient experience to want to participate in the shift to sustainability.

Stefan Sahlmann spoke to Navistar’s focus on battery-electric vehicles (BEVs) as the way of the future, believing strongly in the viability of this technology. He cited studies done in conjunction with industry groups that show BEVs produce the least amount of energy loss from manufacture to utilization in commercial transportation and are the most efficient path to a zero-emission future from a mass adoption perspective, although other technologies like fuel cells may have applications in more niche areas.

Stefan highlighted how Navistar supports customers who want to transition so that implementation is seamlessly operational and economical. Navistar provides consulting programs to help customers plan by analyzing their current operations to determine where electric vehicles can be implemented into an organization’s operations while also consulting on grants, incentives, infrastructure, and charging needs.

Stefan noted that implementing new charging infrastructure at a customer location can take up to 24 months. That’s why Navistar consults with customers on how to plan today for the operations of tomorrow, including supporting conversations with utilities and helping customers find grant programs and incentives to reduce the cost of implementation. As Stefan noted, no one is going to flip a switch and swap out a full fleet tomorrow. But it’s incredibly important to get the conversation started today to

figure out the best, most cost-effective way to begin BEV implementation and plan for infrastructure and inventory availability.

Ian Rust, whose company Revoy provides battery electric services and a managed electrification solution that supports electrification on current internal combustion engine vehicles, added insight into costs and reasons to get ahead. He added valuable color and insight into the importance of starting early due to both market and regulatory pressures. Not being prepared for the transition to ZEVs is a risk for companies as customers start to demand reductions in their Scope 3 emissions, even before regulatory pressures force the issue.

Ian also noted that the cost of a mile on electricity for Class 8 trucks is $0.10/mile vs. $0.60 or $0.70 on diesel, so there are clearly economic efficiencies available if BEVs are implemented appropriately. Further, if a company gets ahead of the competition, both with regards to getting in line with their utilities and offering low-carbon options to their customers, those economic efficiencies and opportunities increase. Companies late to the game may be struggling to provide customers with what they need, as getting their infrastructure in place and acquiring and implementing technologies could take 2 to 3 years.

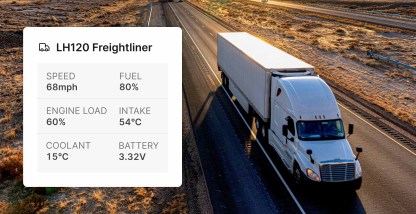

Jai Rangantahan, Motive’s Chief Product Officer, discussed how Motive thinks about sustainability from a product perspective. Motive looks at providing visibility into immediate short-term activities that our customers can do to reduce consumption in their current operations, presenting an immediate economic and sustainability impact, such as improving fuel efficiency with driver behavior, vehicle maintenance, reducing idling, etc., while also working with them on long-term regulatory and environmental concerns. Motive also works to solve customers’ problems by helping determine how to implement ZEV technologies and other technologies in an economical and operationally efficient manner by evaluating data, routing, etc. in our customers’ current operations to help figure out the best and easiest areas to start making changes.

Jai and I wrapped up the session by noting that although the move towards sustainability may involve difficulties, with various pressures and economic issues at play, we came out of the conversation with a lot of optimism because talented, driven, and interested people, like the ones on our panel, are tackling the matters thoughtfully to find solutions that move physical operations towards operating more sustainably. So long as we’re all communicating and solving the problems together, we can tackle these matters efficiently and effectively for a more sustainable future.

How Motive Can Help

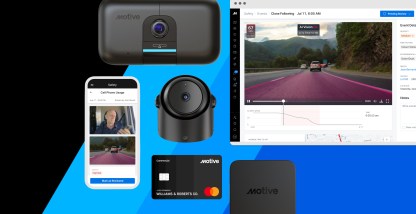

Motive helps customers make their current operations more efficient by giving greater visibility into areas where fuel economy can improve. Our driver coaching platform surfaces fuel consumption and ways for drivers to make improvements. We also provide preventive maintenance, routing and dispatching, and visibility into asset utilization to reduce the amount of waste in our customers’ operations so they can do more with less.

Motive is also building the tools of the future to efficiently and effectively implement new low-emission or zero emission technologies into your operations. We integrate with all types of vehicles, from battery electric to hydrogen fuel cells, and surface them all in the same dashboard as internal combustion engine vehicles for ease of management, communication and visibility. We’re also supporting customers in pinpointing areas to implement new technologies and helping them determine the economic return on investment and total cost of ownership for new vehicles.

Motive also surfaces fuel consumption and carbon emissions on a per vehicle and per trip basis and helps our customers with their emissions reporting.