- Oil is a global fuel with many common modes of transportation

- Modes of oil transportation vary depending on circumstances

- Fleet management technology can help secure oil transportation

Even with growing momentum for renewable energy sources, the dominance of oil isn’t at risk any time soon. For one thing, a majority of the world has only just begun consuming oil. And in the developed nations, the demand for oil is only growing. Moving this important fuel is subject to safety regulations, regardless of the mode of oil transportation. This article will focus primarily on challenges faced by the trucking industry.

What are the most common ways of transporting oil?

Trying to decide how to transport oil is a logistical challenge. Oil and gas are volatile in nature. Transporting oil and gas from processing facilities or refineries takes special care. There are several ways of transporting oil to consider.

Oil transport begins with pipelines. More than a million miles of pipeline globally transport liquid petroleum, either above or below ground. The crude oil is collected from the wellhead and transported by pipeline to processing plants or refineries.

As many sources of oil are overseas, the next mode of transport is by ship or barge. Oil supertankers move between refineries around the world. Barges can move the oil on rivers and seas.

Another option is to move the oil by railway line. This is an alternative to adding more pipeline from refineries or processing facilities. It is cheaper and quicker typically to set up railway infrastructure than to install more pipelines.

Oil and gas is also commonly moved by transport truck. Over-the-road oil transport can move product from remote regions or help to distribute the product shorter distances for industrial and retail use. Fuel tanker trucks are used most often in getting the cargo to gas stations or manufacturing centers.

Advantages of transporting oil by truck

Tank trailers and trucks can more easily reach places where there is no railway infrastructure or ships and pipelines can’t get to. Transporting oil and allied products by road can also be more efficient. A trailer can be built with compartments allowing for different amounts of various oil products to be transported at once. This can save time and money. Instead of having to take several trips, a delivery can be made in one.

Tank trailers are also affordable to manufacture, which can help to meet surges in demand. So, while trucks don’t offer the storage capacity of the other modes of oil transportation, they do bring flexibility to the mix.

Risks of transporting oil by truck

Each of the modes of transporting oil has its own drawbacks. For this article, we’ll focus on the risks of transporting oil by truck.

Oil transport truck drivers have a challenging job. They are often operating large, heavy vehicles with a hazardous or flammable cargo. They have to adapt to driving a liquid cargo that shifts in motion. If the liquid oil is in one compartment, it will move in different directions when the vehicle turns or goes or down a hill. This changes the center of mass, which affects the vehicle’s stability. Plus, there’s a big difference between driving a full oil transport truck and an empty one.

Additionally, drivers have even more safety precautions and regulations to follow. This is hazardous material (hazmat) driving, which means a violation can result in steep financial penalties.

What safety regulations govern oil transport by truck?

Oil transport truck drivers must adhere to regulations set by the Federal Motor Carrier Safety Association (FCSMA). In addition to the rules for any commercial driver, oilfield commercial drivers must also:

- Have at least one 30-minute off-duty break if driving for more than eight hours.

- Not drive for more than 11 hours within a timeframe of 14 hours.

- Not drive for more than 60 hours within seven days.

The hours-of-service regulations for commercial drivers also apply. However, there are some exceptions available to oilfield drivers. These include exemptions around the 24-hour restart rule, waiting time, and split breaks.

Learn more about the hours-of-service rules for oilfield drivers and how to reduce oil and gas fleet downtime.

Common oil transportation problems encountered by trucking fleets

Generally, tanker trucks are used to carry small quantities of oil short distances. Truckers also rarely carry crude oil. Still, there are some oil transportation problems that trucking fleets need to consider.

The first, most obvious problem is the volatility of the cargo. Crude oil is also destructive when spilled, as it’s toxic to humans, animals, and the environment. Spillages and accidents must be mitigated. A collision could mean direct contact with the public on a highway or in a densely populated neighborhood.

Additionally, inefficiency in fleet management from natural fields to manufacturing facilities can lead to significant quality loss. So, process efficiency and route optimization matter. Yet transportation on land can suffer from uneven roads and poor infrastructure.

Then, there are the issues with truck design. Tanker trucks are typically loaded from the bottom to make the journey. But extracting it from the tank at the destination is difficult. Residue oil can stick to the bottom of the truck. Called wetlines, these persistent remnants can contribute to fires or other accidents.

All these considerations are part of the reason screening labor is so much more important in oil transport. Even though there’s a driver shortage, the drivers entrusted with taking tanker trucks on the road need to be more experienced and trained to handle the extra challenges of transporting oil.

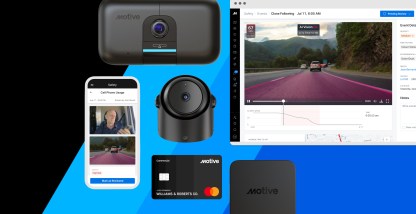

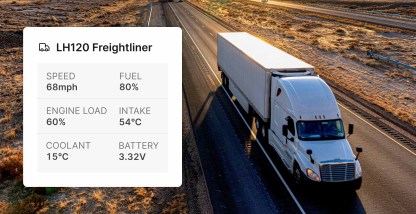

How to transport oil safely with Motive

Motive’s fleet management software supports safe oil transportation. Cut the risks associated with transporting oil by truck with the added visibility offered by GPS tracking. Fleet managers can see where trucks are and message drivers to coordinate dispatches and optimize routes. The oil transportation company can also protect its assets with real-time tracking and geofencing features.

By leveraging in-cab dash cams, fleet managers can also keep drivers and their cargo safer. Real-time alerts to drivers help reduce the frequency and severity of accidents. Fleet risk managers can also provide ongoing training with automated, personalized coaching to modify driver behavior.

Prioritize cargo safety and protect drivers while benefitting your bottom line with Motive’s fleet safety solution. Learn more today.