If you’re asked, “What is lead time in shipping?” would you be able to respond confidently? Would you also be able to concisely explain how it’s different from delivery time? Or explain the importance of lead time in shipping?

This article provides answers to key questions about lead time in shipping and shares strategies to improve it.

What does lead time mean in shipping?

Lead time in shipping is the time gap between when an order is placed and when it arrives at its final destination. Take a teenager buying a pair of sneakers online. Once those shoes are paid for, the order is submitted for someone to pick and package. Once the order’s fulfilled, it’s collected by a shipper from the primary supplier for delivery to the recipient. All of these actions are involved in shipping lead time.

There are also other types of lead time. Cumulatively, you may need to also account for:

- Material lead time: How long it takes to order the supplies and receive them

- Production or manufacturing lead time: The time a company takes to produce and deliver the products

Cumulative lead time can be impacted by production process times, supply chain availability, and inventory management practices. Lead time will be much longer if the manufacturer needs to order raw materials to produce the product. If that’s the case, you’ll need to wait for those materials to arrive for product manufacture.

Is lead time the same as delivery time?

Lead time is different from delivery time. Shipping lead time includes the time spent processing and handling the goods as well as the time spent on delivery. Delivery time, however, only accounts for the time from cargo collection by the shipper and delivery to the recipient.

Keep in mind, customers only care how long they have to wait for the order to arrive.

Why is lead time important in shipping?

Customers want their deliveries to arrive promptly. Poor shipping experiences can lead to customer attrition, one reason that lead time is so important in shipping. Longer lead times can also create inefficiency and excessive inventories, which inflate costs. Understanding shipping lead times helps workers set realistic delivery dates and meet customer expectations.

How to calculate lead time in shipping

To calculate lead time in shipping, you need to know the amount of time it takes to fulfill a customer order after the order is placed. Transportation lead time will vary depending on inventory management practices.

Take a made-to-order T-shirt company, for example. Once someone orders their shirts, it could take a day to get the shirts from the warehouse and another day to prepare the design. Printing and packaging the shirts takes another four days. That’s a four-day shipping lead time.

What factors can affect lead time in shipping?

Shipping lead times can be impacted by material shortages, labor shortfalls, or shipping delays. If the T-shirt company above doesn’t have the right red shirts in stock, they can’t move on to design and printing. Or, if there aren’t enough people working in the factory or in the warehouse picking and packing, lead time can grow longer. Shipping delays at any point can also cause lead time variability.

Strategies to help reduce your shipping lead time

Knowing customers want fast delivery, you need to look for ways to reduce your shipping lead times. The following strategies can help.

Optimize inventory management

Following lean business management principles and using just-in-time inventory management can shorten material and factory lead times. With a full understanding of lead time you can better set your reorder levels to avoid stockouts or having to worry about lost sales from back orders.

Streamline internal processes

Unwieldy processes to fulfill a customer order can make lead times lag unnecessarily. Outsourcing pre-production can help reduce shipping lead time. Automating fulfillment or inventory processes such as stock-taking or tracking purchase orders may help as well.

Partner with reliable shippers

A manufacturer or e-commerce retailer may be doing everything in their power to optimize lead time, but it can all be for naught if the shippers are slowing things down. Monitoring delivery success rates for different shipping partners can help ensure that you partner with the ones that get your goods where they need to be at the right time.

You might consider adding lead time-related stipulations to your contracts with shippers. This might include specifying delivery times, penalties for shipping delays, or advance notice of price changes.

Try dropshipping

Dropshipping takes out the middleman. In this model, the retailer doesn’t stock their own inventory. Instead, they rely on the supplier to directly ship the product to customers. The dropshipping business handles the inventory and fulfillment logistics.

How Motive can help improve your shipping lead times

Motive can help decrease lead times by speeding up the physical delivery of the goods and streamlining last-mile delivery.

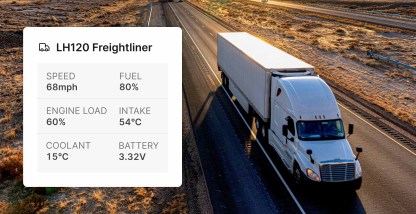

Route optimization is central to Motive’s delivery fleet management solution. Using traffic and location data as well as GPS tracking, Motive can efficiently plan delivery routes that are both time- and cost-efficient. With live updates, fleet managers can also save time and money by rerouting drivers or avoiding congestion or weather hazards.

Avoid last-minute delivery problems as well with access to the data you need about everything from fuel costs to warehousing, idling, and downtime. You can expedite last-mile delivery and improve profits with Motive’s comprehensive fleet workflow solution helping to reduce fuel usage, minimize vehicle breakdowns, control overhead, and prevent collisions.

The data you get from Motive’s AI-driven platform can help your lead time analysis. Being able to easily see how long it takes for products to be prepared and shipped can mean faster fulfillment rates, which lead to greater customer satisfaction. Find out more today.