Connectivity is transforming the construction industry. Try to find a new machine from a major manufacturer rolling off the line today without telematics installed. This article will provide an overview of construction equipment telematics, what assets use construction telematics, and the many benefits of a construction telematics solution.

What is telematics in the construction industry?

Telematics blends telecommunications and informatics. It transmits data over various networks to increase operational visibility. Across industries, a telematics system and fleet management software can help fleet managers and decision-makers improve day-to-day workflow to work smarter, faster, and with fewer problems.

For more than a decade, the construction industry has been embracing the potential of this technology to improve efficiency, reduce costs, and boost profits. Gathering GPS telemetry and on-board diagnostics, construction telematics offers greater understanding of heavy equipment and fleet asset data.

The use of telematics is growing common for construction equipment and vehicles. In a recent study conducted by B2B research firm, Markets and Markets, predicts a compound annual growth rate of 17.2% by 2026. That’s an increase from an estimated $676 million market value in 2021 to $1,498 million by 2026.

According to the study’s findings, the growth is driven by new product launches, government safety and ELD mandates, and increased interest in autonomous equipment.

How to use telematics in construction?

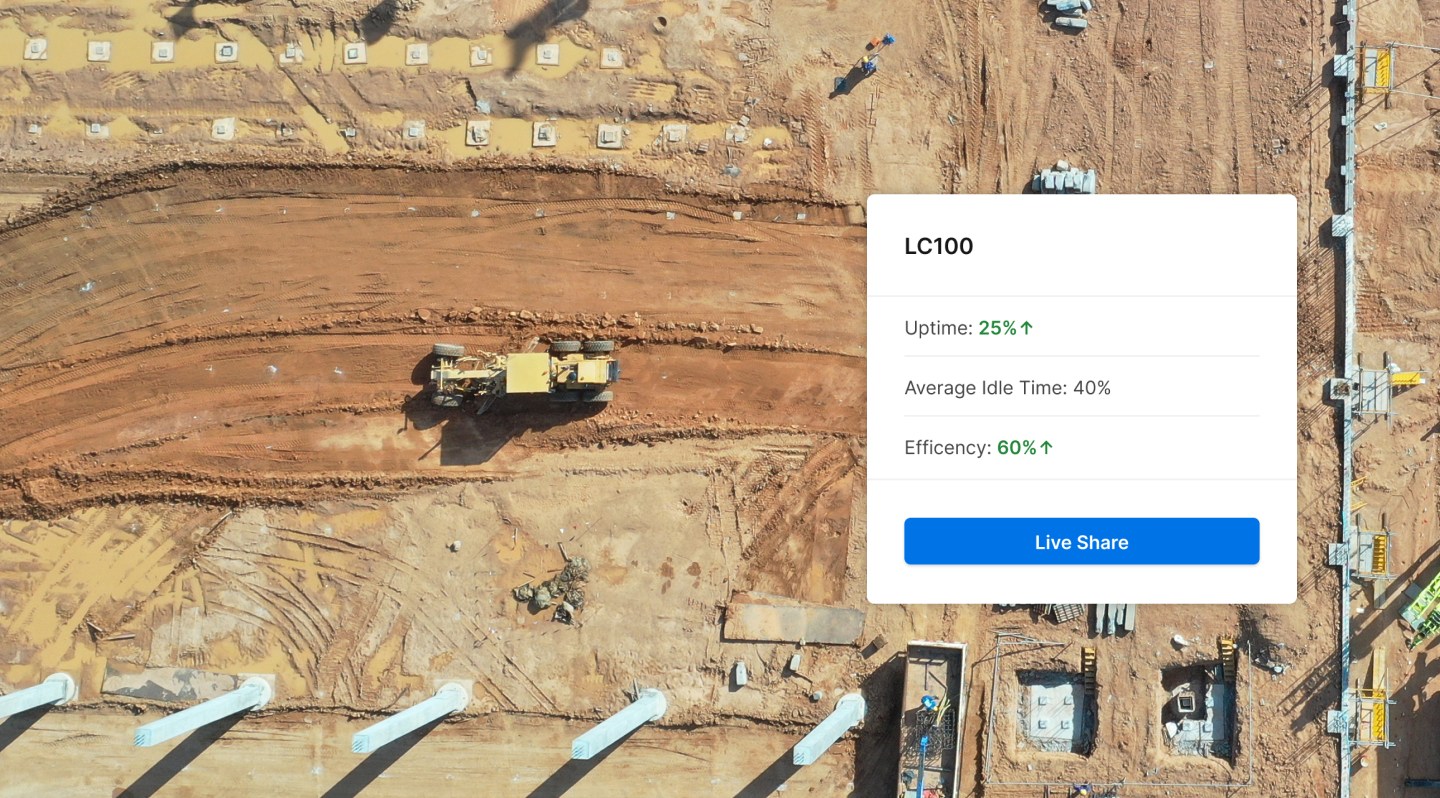

Construction sites can be busy, dynamic places.. There will be many different types of asset (equipment, vehicle, and personnel) on a job site on a given day. Top-rated construction telematics installed in or on heavy-duty vehicles and other equipment lets the company track and transmit its assets’ whereabouts via real-time GPS and asset tracking.

But that’s not all a telematics solutions for construction offers. Sensors and on-board diagnostics can transmit vehicle location, driver behavior, vehicle activity, and real-time engine diagnostics.

Without having to be onsite, the fleet manager can collect and transmit information about:

- Vehicle maintenance issues

- Vehicle usage

- Fuel consumption

- Rapid acceleration

- Hard braking

- Hard cornering

- Idling time to minimize fuel wastage

- Speeding

Can you use telematics for construction equipment?

Construction equipment telematics is available for all prime pieces of equipment. OEMs are now also making it possible to retroactively outfit dozers, excavators, backhoes, and the like to remotely view fuel level, fault code, and maintenance data.

Telematics equipment for construction offers several benefits including the ability to analyze asset allocation. With the real-time data available, it’s possible to see whether equipment is sitting unused at a project. Or you could identify that there isn’t enough equipment onsite. With this awareness, you can minimize machine overuse and steer clear of unexpected downtime.

The telematics technology helps a business track the maintenance and repair schedules for equipment. Or, if you’re renting equipment, the data can help you recognize where you could adjust your equipment needs to reduce costs, which is just one benefit.

Further, does telematics in construction help combat theft? It certainly can. Many telematic softwares enable GPS tracking and geofencing or time-fencing. This lets operators monitor equipment from remote locations. Alerts can be sent if equipment is operated outside of set boundaries or scheduled work hours. In the event that equipment does go missing, the tracking technology can help you to locate that asset for faster recovery. Some systems even let you remotely shut down the equipment if unauthorized use is detected.

Can you get construction fleet telematics?

Construction equipment telematics similarly help with optimizing allocation of vehicles and improved awareness of maintenance needs. At the same time, construction telematics can reduce fuel consumption as you gain the ability to monitor idling versus work time.

Telematics data can also improve operator performance. The fleet manager can identify bad habits such as speeding, machine overloading, or erratic braking and correct those behaviors. Coaching operators to improve the efficiency of their use of fleet assets can reduce wear and improve worksite safety as well.

We’re also asked, “Can construction telematics save fleets money long term?”

Yes. There are many ways that telematics can help fleets reduce costs. The reduced wear on assets and theft prevention already mentioned can cut expenses. Additionally, some insurance providers reduce the premiums on fleet vehicles with telematics installed for GPS fleet tracking and geofencing alerts.

Your business can also do more accurate job costing with the telematics data available to understand machine hours and fuel usage.

Features to look for in a solution

Telematics in the construction industry are used primarily to monitor and report on all assets; automate maintenance management; and locate lost, stolen, or missing assets. When selecting your telematics solution for construction sites, look for the following features:

- One window transparency. You’re probably working at more than one site at once, so you’ll want to be able to track and monitor your assets all in one easy-to-navigate dashboard.

- Customization capabilities. Look for the ability to set your own filters and build your own reports based on business needs.

- Mobility of data. A cloud-based software will make it possible for your users to access telematics data from mobile devices, tablets, laptops, or desktops.

- Ability to set alerts. Geofencing and time-fencing can help prevent theft and make you aware of any unauthorized usage. Scheduling usage alerts can also help managers avoid equipment overuse.

- Maintenance automation tools. Manage preventative and predictive maintenance with telematics tracking, which helps reduce unexpected equipment failures.

- Driver metric tracking. Increase productivity and improve safety and compliance with the tools to view performance trends and set benchmarks.

Why use Motive as a telematics solution?

Motive’s telematics solutions for construction offer all the important features needed to track assets and vehicles, monitor usage and fuel costs, set helpful alerts, and keep operators performing their best.

Avoid common challenges of the chaotic construction site with the ability to quickly see day-to-day asset and equipment usage, and identify areas where efficiency can be improved. Instead of having to call job sites to locate equipment and learn employee ETAs, fleet management software can provide automated notifications to improve planning.

Billing can get easier and more accurate as well. Geofencing simplifies equipment tracking to quickly determine what equipment is being used at which site, and for how long, to make billing smoother.

Motive’s solution for construction equipment telematics helps you ensure job site safety and federal compliance as well. Motive’s fleet management software also collects driving behavior data and can rank drivers based on a safety score. Fleet managers can use this information to identify drivers who need coaching and improve the overall level of safety across the fleet.

Discover how construction telematics can benefit your fleet and business. Request a free demo of Motive’s telematics solution today.