When a vehicle’s onboard diagnostics system detects a malfunction, it generates the appropriate diagnostic trouble code and usually alerts the driver via a warning light or other indicator on the vehicle’s instrument panel. These trouble codes are often referred to as Diagnostic Trouble Codes (DTC) codes.

DTC codes help you understand what needs to be fixed so you can keep your vehicle operational and safe.

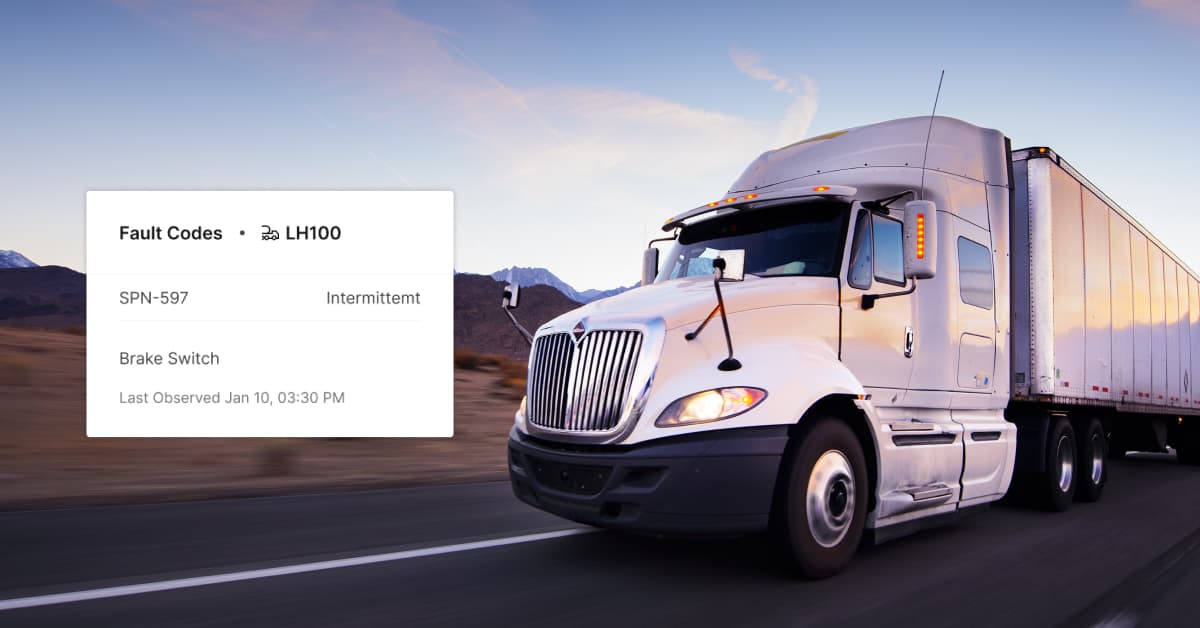

If you have a fleet management software system in place, the DTC codes will be sent in real-time to a fleet manager or technician. Having the right vehicle diagnostics system in place to deliver fault codes in real time will help keep your fleet running more efficiently and smoothly.

Understanding DTC codes and how they integrate with your fleet software solution can help improve driver safety and deliver healthy ROI.

Learn how Motive Maintenance can help you reduce downtime. Request a demo to see it in action.

DTC meaning: What is a DTC code?

What does DTC mean, and what are DTC codes? Let’s start by explaining the DTC meaning first.

DTC stands for Diagnostic Trouble Codes.

A DTC code is a series of diagnostic trouble codes used by a vehicle’s onboard diagnostics (OBD) system to alert you when a vehicle experiences a malfunction. Different codes have different DTC meanings and represent specific problems in your vehicle.

When the vehicle’s OBD system detects a problem, it generates a specific DTC code and transmits the alert to the vehicle’s instrument panel as a warning light. In vehicles equipped with a telematics system, the alert can be delivered directly to the fleet. The system can be set up to deliver the alert right to the maintenance department.

These codes were created by the Society of Automotive Engineers (SAE) to help vehicles comply with emission regulations. SAE is now called SAE International, and it is a professional organization that develops standards for automotive engineers.

Standard diagnostic trouble codes list

If a vehicle’s manufacture date is 1996 or newer, it will most likely be OBD-II compliant.

The vehicle’s electronic system performs self-diagnosis and reporting. Any time the system detects a problem, it records that problem as a code. That code is known as a (DTC) diagnostic trouble code.

How do DTC codes work?

Diagnostic Trouble Codes or OBD-II (in light-duty vehicles) or J1939 (in heavy-duty vehicles) trouble codes are codes that the vehicle’s OBD system uses to notify you about a problem. Each code corresponds to a fault detected in the vehicle. When the vehicle’s computer detects an issue that requires attention, it will activate the corresponding trouble code.

What does a DTC mean in a vehicle?

The engine control module (ECM) functions as the main computer on all newer model vehicles. The ECM is also commonly referred to as the engine control unit (ECU) or powertrain control module (PCM).

When your vehicle’s ECM is directly connected to your company via telematics, app, or gateway, you can find out in real-time from your desk in the home office what’s going on with the vehicle. Motive’s vehicle diagnostics automatically monitors fault codes through its direct connection to onboard vehicle diagnostics.

Diagnostic trouble codes you need to look for

Motive’s onboard diagnostics monitoring system helps you avoid costly repairs and reduce vehicle downtime. With real-time notification and a description of the fault code, the fleet manager can make the appropriate decision. That may be to drive to an outside shop or have the driver return to the carrier’s home base for repairs.

Having one person monitor incoming telematics from the entire fleet brings significant advantages. For instance, the data can be used to route drivers and assign loads to trucks that do not need service.

Over time, a company can learn how to prioritize data and look for trends. This allows the company to use preventive maintenance and extend the life of its fleet by optimizing the availability of the assets.

Types of DTC codes:

With the number of generic and manufacturer-specific DTC codes that could appear on your vehicle, it can be difficult to understand all the fault codes.

If you can’t fully understand your DTC codes even after reading your vehicle manufacturer’s manual, make sure to check with your mechanic instead of purchasing replacement parts for the component or system right away.

DTC codes can be categorized into two types:

Type 1: Critical codes

These are urgent DTC codes that can cause quick and severe damage to the vehicle.

DTC codes such as high engine temperatures and low coolant levels could mean that engine failure is imminent. With real-time vehicle diagnostics, fleet managers and technicians can act quickly. They can assess the severity, recommend appropriate action immediately, and locate the nearest service center to resolve the issue before it becomes a costly and critical situation.

Type 2: Non-critical codes

While these DTC fault codes do not need urgent solutions, they still require proper attention. This includes emissions-related engine DTCs that don’t lead to excessive pollution.

Non-critical codes include those that light up the Malfunction Indicator Lamp (MIL), also known as the Check Engine Light. Type two codes also store a freeze-frame that has failed consecutively after two driving cycles.

Interpreting DTC codes

A DTC code is five characters long. You’ll get more familiar with these over time, but there are thousands of different codes, so as a driver or fleet owner, you want to know how to find the definition for any code you see in your vehicle. If you have a good comprehensive fleet management solution, the meaning of each code will be provided to you each time you are alerted with a code.

Codes are standard, and you’ll know what area of your vehicle the code refers to if you understand the structure of the code and the standard abbreviations.

The first character (letter)

OBD-II codes start with a letter that denotes the part of the vehicle that has a fault.

- P – Powertrain. Includes engine, transmission, and associated accessories.

- C – Chassis. Covers mechanical systems and functions: steering, suspension, and braking.

- B – Body. Parts that are mainly found in the passenger compartment area.

- U – Network & vehicle integration. Functions that are managed by the onboard computer system.

The second character (number)

The first letter is followed by a number, usually 0 or 1.

- 0 – Standardized (SAE) code, also known as generic code (sometimes called global)

- 1 – Manufacturer-specific code (sometimes called enhanced)

The third character (number)

For powertrain codes, this number tells you which vehicle subsystem has a fault. There are eight:

- 0 – Fuel and air metering and auxiliary emission controls

- 1 – Fuel and air metering

- 2 – Fuel and air metering – injector circuit

- 3 – Ignition systems or misfires

- 4 – Auxiliary emission controls

- 5 – Vehicle speed control, idle control systems, and auxiliary inputs

- 6 – Computer and output circuit

- 7 – Transmission

You may also see an A, B, or C, which can refer to hybrid propulsion systems.

For other families of codes, refer to the definitions provided by your manufacturer.

The fourth and fifth characters (number)

The final piece of a DTC is a number that defines the exact problem that you’re experiencing. It can be a number between zero and 99.

Here’s an example of a complete code:

P0782 means powertrain, generic, transmission, 2-3 shift malfunction.

The best source for DTC meanings is the dealer that sold or leased the truck to you or the manufacturer who made it. Some DTCs are specific to the vehicle. Download the complete list to your device so that you can access it any time, including in areas where cellular service may be spotty. Or consider implementing a vehicle diagnostics software solution that provides definitions for you.

How to read DTC fault codes

You need a diagnostic connector to read DTCs. Most scan tools provide codes in one-line descriptions, and some will include the DTC meanings.

Basic code readers or scanners typically only give you the five-character code. To get the definition, you’ll need to check a standard DTC list or database and your manufacturer’s website and reference material for your vehicle’s specific model.

Using a robust fleet management solution will give you complete code definitions automatically provided with your fault alerts.

Plug the scanner into your vehicle’s 16-pin OBD-II diagnostic connector, commonly located on the steering column’s left side and under the dashboard. However, since connectors aren’t universal, vehicle diagnostic connectors manufactured before 1996 will require specific adapters.

The latest vehicle models generally have the same connectors, but variations in the software and hardware depend on the vehicle’s make, model, and year.

To read DTC fault codes using a scan tool, follow these general steps.

- Find the location of the 16-pin in the vehicle. Some connectors are in the center console, and other vehicles might have them hidden behind a knee bolster panel or other types of panels. Consult the manufacturer’s vehicle manual to find the OBD-II diagnostic connector if it’s not in any of these locations.

- Plug in your code reader or scanner and turn on the ignition or keep the engine running (depending on your vehicle’s OBD requirement). This allows the scan tool to communicate with your vehicle’s ECU.

- From the tool’s menu, select the option for “read codes.” You might need to enter specific information such as the vehicle model and year if your scanner isn’t set to get this data automatically.

- The scan tool will then show any present DTC faults, and usually, in numerical order. In some tools, these will include the code definitions. Most of the latest scanners allow you to transfer the codes to a smartphone or computer via Wi-Fi, USB code (if available), and Bluetooth.

While DTC codes provide valuable information about potential vehicle problems, these are meant to act as guides to find underlying issues and further diagnose the root of the defective and malfunctioning vehicle components.

Also, clearing codes won’t make the vehicle issues disappear. This can even be dangerous and lead to vehicle failure and expensive liabilities that can cost you thousands of dollars down the line.

Besides an OBD-II or DTC scanner, reliable telematics systems and devices provide more efficient ways to read and monitor engine diagnostics.

Telematics systems can track your vehicle’s engine and systems in real-time, alerting you to any problems as they arise promptly.

Robust telematics systems can easily detect DTC codes and automatically transmit the information to your fleet managers, staff, and drivers, allowing quick action and response.

This improves your preventive maintenance process, reducing your unplanned repair costs.

Reading a J1939 DTC

A J1939 consists of four fields that relay data about the fault the DTC is reporting, which are:

- Suspect Parameter Number (SPN) – This represents the SPN with error, and each one can be used in a DTC. It describes the parameter by providing the data type, data length in bytes, range, resolution, reference tag or label, and offset.

- Failure Mode Identifier (FMI) – This represents the type and nature of the error, such as sensor short-circuits, calibration error, value range violation (either high or low), and incorrect update rate.

- Occurrence Counter (OC) – This counts the number of the error condition’s occurrence for every SPN. The OC also stores this information even when the error is already inactive.

- SPN Conversion Method (CM) – The CM describes the byte alignment in the DTC.

Popular DTC codes list

While vehicle trouble can vary depending on the vehicle’s condition or issues it encounters, there are some DTCs and their corresponding malfunctions that most fleets encounter, such as:

- P0101 – A Mass Air Flow (MAF) circuit or sensor fault

- P0110 – An intake air temperature sensor circuit malfunction

- P0442 – A small system leak within the vehicle’s evaporative emission control system

- P0500 – A malfunction in the vehicle’s speed sensor

- P0606 – A PCM (or ECM) powertrain malfunction

- P0706 – A transmission range sensor circuit range fault

DTCs provide useful information to help identify vehicle malfunctions, but they are not the ultimate way to figure out why the malfunction happened.

With the help of DTCs, malfunctioning vehicle components will need further assessment and diagnosis by mechanics to pinpoint and fix the cause of the issue (or issues).

DTC meanings, codes, and fleet management systems

Information gathered by a vehicle’s telematics system can include vehicle speed, fault codes, fuel usage, engine RPM, and other details. This data can be uploaded to a software interface to allow the fleet owner to efficiently monitor performance, vehicle health, and trip start and finish details.

Without a reliable fleet telematics system in place, you may need to rely on your drivers to let you know what codes are displayed. This may not be the most efficient way to handle issues that come up. If a driver doesn’t let you know there is a DTC code that needs to be addressed, you may not become aware of a serious maintenance issue right away, and the problem could worsen before it’s fixed.

You may also need to rely on drivers to give complete and accurate information to mechanics or other repair personnel. Unfortunately, at least half of all vehicles that leave a mechanic’s shop as “fixed” still have at least one unresolved issue.

A fault code, on the other hand, can give information about underlying issues that the driver may not be aware of.

Clearing DTCs

Most first-generation OBDs in vehicles used before OBD-II allowed you to disconnect a battery cable or the computer’s power source, and it would erase the fault codes.

The voltage loss would erase the computer’s temporary memory, and the Check Engine Light would stop lighting up. However, the light would turn back on, and the codes would reset when the original issue recurred.

With the latest OBD computer systems, DTCs get stored in a “non-volatile” memory that remains even if the battery or computer is disconnected. The fault codes are kept intact until you or mechanics clear them using a scan tool.

Clearing DTCs by disconnecting the computer’s power supply or battery isn’t recommended since it can lead to a climate control system and electronic radio preset loss.

It can also result in losing the engine computer system’s “learned” memory which is almost impossible to recover since it contains the adjustments made over time to compensate for driving habits and engine wear.

The engine’s computer might also need to be put through a particular learning process to relearn the proper transmission operation in case of power loss on vehicles where the engine computer also controls the electronic transmission.

Automating the DTC process

When you employ a good telematics system, DTC codes can go straight to the fleet desk. The dispatcher can tell the driver how to handle the issue and at the same time send another vehicle to take over the load if needed.

A truck equipped with an OBD-II port can quickly and easily connect to a fleet tracking system. The Motive vehicle diagnostic system is an example of a top-rated plug-and-play ELD and fleet management device.

On-board diagnostics make telematics and fleet solutions possible. Without OBD, there would be no way to transmit data. With a good vehicle diagnostics system, you can catch maintenance issues early. The Motive vehicle diagnostics gateway features help you:

- Monitor fault codes through a direct connection to on-board vehicle diagnostics

- Diagnose vehicle problems in real-time, some before they occur

- Monitor speed, idle time, and other details

- Track wear and tear – calculate trends to find out what parts wear out faster than others

- Catch and address important issues that are highlighted in reports

What your drivers need to know about DTCs

Never ignore the check engine light when it comes on and stays on. A check engine light or malfunction indicator lamp (MIL) that stays lit is an indicator of a critical problem with your vehicle that calls for urgent attention.

Lit up MIL is only one of the many vehicle indicators of DTC faults, and they can switch on when the problem affects emissions.

DTC faults can also turn on other lights, including the Supplemental Restraint System (SRS) in light trucks, airbags, etc.

Depending on the vehicle’s system configuration and problem, the MIL light can switch on and off or continuously light up.

Most vehicle engine computers often set themselves to a backup mode when the MIL light illuminates to allow the vehicle to keep running until the problem gets fixed.

However, this “limp-home” mode can use up tons of fuel, making it crucial to address the fault quickly.

Ensure drivers and staff don’t clear DTC fault codes using an OBD scanner without getting the vehicle problem fixed first.

Not only can this lead to further vehicle damages, but also failed emission testing. Emission testing center inspectors use their own OBD scanners, allowing them to find DTC codes, and they can easily reject your vehicle.

Additionally, never take your vehicle for an emission test if its current battery has been previously disconnected, newly replaced, dead, or lowly cranking.

Vehicle batteries that go below five volts will wipe out the computer memory, and without it, your vehicle will automatically fail the emissions test.

If your company has an onboard vehicle diagnostics system installed, contact your fleet manager. They should have received a fault code notification on their computer with a detailed description and can instruct the driver of the DTC meaning and next steps to resolve the issue.

Get started with Motive Maintenance

Learn more about the Motive Vehicle Diagnostics feature and how it can help you with vehicle maintenance, driver safety, reduced operational costs, and increased efficiency.

Call us at 844-325-9230 with questions or book a demo to see how it works in real-life scenarios.