Fleet preventive maintenance is among the most cost-effective ways to lengthen the service life span of a vehicle or asset, improve fleet efficiency, and minimize vehicle breakdowns.

Ignoring regular preventive maintenance work can hurt a company’s bottom line in the long run. That’s why having an established preventive maintenance system is crucial. In this guide, we’ll cover the ins and outs of fleet preventive maintenance.

Learn how Motive Maintenance can help your fleet stay ahead of costly repairs.

What is preventive maintenance (PM)?

Preventive maintenance (PM) is a proactive, periodic, and routine upkeep of vehicles, equipment, and other business assets. The purpose is to keep assets in optimal conditions, maximize availability, and prevent sudden, expensive malfunctions and subsequent downtimes.

Fleet managers perform preventive maintenance while their vehicles and assets still function well. PM activities often include scheduled servicing, vehicle inspections, repairs, lubrication, cleaning, adjustments, parts replacement, and testing.

Are there different types of preventive maintenance?

Fleet managers can perform different types of preventive maintenance. These include:

1. Time-based preventive maintenance

Also known as calendar-based or periodic maintenance, this type requires vehicle maintenance after predefined time intervals (such as monthly, quarterly, or yearly). It’s the most straightforward and common kind of preventive maintenance designed to inspect vehicles regularly.

This primarily calendar-oriented attribute makes time-based maintenance different from predictive maintenance. The latter relies more on real-time fleet health data than schedules for performing the right upkeep activities.

2. Usage-based preventive maintenance

Rather than relying on maintenance schedules, this type uses a more asset-specific procedure that fleet managers use and log in meter readings via software.

When specific measurements are reached, the software notifies users to conduct maintenance. For instance, fleet managers can schedule their company trucks for maintenance for every 5,000 miles traveled.

Measurement readings can be in units of the service hours, gallons of fuel consumed, or the number of miles traveled.

3. Failure-finding maintenance

For this approach, operations managers inspect vehicles and perform deliberate actions to uncover failures or defects.

An example is lighting a cigarette near a vehicle to cause it to detect smoke and trigger its smoke alarm. If it doesn’t, managers can check the part’s condition and apply proper corrective action.

4. Prescriptive maintenance

Prescriptive maintenance is ongoing. Similar to predictive maintenance, this type uses machine learning (ML). The ML technology obtains and analyzes data to develop specialized recommendations and drastically reduce operational risks. It continues to monitor your equipment to make sure its recommendations made a positive impact.

How to establish a preventive maintenance schedule and program

To develop an effective fleet preventive maintenance program, you may need the following:

- A checklist of all preventive maintenance activities to implement according to schedule (more on this later)

- The service intervals or frequency of performing preventive maintenance tasks on every vehicle in your fleet

- A system for drivers to send and customize their vehicle inspection reports

- A process for drivers to document vehicle incident reports, e.g., breakdowns, symptoms indicating engine issues, etc.

- In-house or outsourced automotive facilities and qualified technicians to run maintenance activities, inspections, and repairs

- Systematic record-keeping procedures

- Clear processes for ordering necessary vehicle parts and maintaining an inventory of spare parts

- Tools and methods for efficiently tracking relevant metrics

Next, take the following actions to establish your commercial vehicle preventive maintenance schedule:

Set up a baseline

Have a clear overview of your vehicles’ present conditions by running a thorough inspection and documenting all available information, including each vehicle’s utilization and fuel efficiency, maintenance and repair history, replaced parts, manufacturers and vendors, and more.

Every vehicle in your fleet must have an updated service and inspection record, plus a baseline of its current fluid levels, mileage, and other information.

Decide on your maintenance intervals

Determine each vehicle’s preventive maintenance schedule according to its type, operating conditions, and other critical factors.

Choose which metrics are crucial to monitor for every vehicle and the triggers or data points that will prompt you to perform pertinent preventive maintenance activities.

Create functional driver inspection and reporting systems

Commercial drivers are usually the first to notice indications of vehicle maintenance issues. Partner with drivers by assigning them to monitor anything suspicious regarding:

- Vehicle operating behavior

- Vehicle safety-related parts and systems

- Vehicle body and interior

- Miscellaneous items

Set up straightforward reporting systems for drivers and train them on the corresponding procedures.

Monitor maintenance and performance metrics

Establish and track key performance metrics and improve your maintenance activities according to the results and insights you obtain.

Some examples include:

- Frequency of performing preventive maintenance against that of unscheduled repairs

- Number of years the vehicle was in excellent condition versus its average pre-PM lifespan

- Costs spent on preventive and reactive upkeep, and more

What are the benefits of a preventive maintenance program?

Running an effective preventive maintenance program benefits you in several ways:

Improved vehicle reliability

Well-kept commercial motor vehicles can provide reliable service and enable you to maximize their availability. Drivers can confidently use them anytime without worrying about vehicle breakdowns or operational hiccups.

Fewer repairs

By proactively and regularly maintaining your vehicles, you can uncover issues in the initial stages and prevent them from becoming worse. This can help you save huge expenditures and larger-scale repairs, which directly impact a business’s bottom line.

Longer vehicle service life

Timely and effective fleet preventive maintenance preserves the vehicle’s best operating conditions. This increases their chances of functioning properly for a long time. Your cost of ownership lowers, and you can avoid expensive breakdowns, major accidents, and premature replacement of parts.

Improved fleet productivity

With well-maintained vehicles, you get fewer disruptions and increase your operational and vehicular efficacy. Motor vehicles in better conditions will likely perform better, enabling you to deliver loads on schedule, take on more contracts, and keep customers happy with timely deliveries.

Preventive maintenance also stops you from losing revenue and man-hours spent waiting for towing machines or completing repairs.

Truck preventive maintenance checklist

A truck preventive maintenance checklist or truck PM checklist can help your fleet stay more efficient and productive. If your fleet has large commercial trucks, here are some activities to include in your PM service checklist:

- Performing general tune-ups regularly

- Replacing engine oil and filters regularly

- Checking electrical system components

- Inspecting your vehicles’ cooling and fuel systems

- Checking, filling, or changing the transmission fluid as necessary

- Looking into and repairing any fluid leaks

- Replacing tires periodically, such as during seasonal changes

- Assessing the transmission and engine mounts

- Checking the charging, starting, and air systems

- Examining the body of the vehicle, mirrors, and glass

- Inspecting and rotating rims, wheels, and tires

- Looking through and addressing issues with the horn and auxiliary systems

- Evaluating and replacing (if needed) CV joints, hoses, driveshafts, and belts

- Ensuring the exhaust system functions well

- Changing the windshield wipers and filling up the windshield fluid reservoir

- Evaluating the suspension and steering systems

- Verifying the conditions of the frame and undercarriage

- Inspecting the exterior and interior lights

- Examining seat belts and seat structures

- Assessing the brake system and changing brake rotors and pads if necessary

Keep in mind that preventive maintenance activities for every vehicle classification may vary. Some may require more regular fluid or parts replacements while others may need more rigorous compliance inspections.

Develop a preventive maintenance checklist specific to each vehicle type in your fleet and include the vehicle manufacturer’s recommendations.

Can you get preventive maintenance software and tools?

It’s often burdensome to stay on top of all your preventive maintenance to-do’s, particularly if you’re using paper-based plans and checklists. An excellent alternative is to use robust preventive maintenance software.

Using a preventive maintenance software solution can also help automate processes and keep reports and historical data intact. It equips your team with efficient tools to inspect vehicles thoroughly, minimize downtime, and boost productivity. It also allows you to monitor the health of all the vehicles in your commercial fleet more closely and comprehensively.

Finally, using a preventive maintenance schedule software makes scheduling your maintenance work much easier and streamlines processes, so your daily operations aren’t disrupted.

There are numerous preventive maintenance tools available in the market, but it’s crucial to pick the right solution that fits your business needs.

Features you get in the best preventive maintenance software

Not sure which preventive maintenance solution you should go with?

Here are some top features that the best preventive maintenance software should have:

Automated maintenance workflows

An efficient preventive maintenance schedule software automates tasks, creates functional workflows, and tracks work orders and progress.

The software should also simplify the coordination in performing preventive maintenance, and store as well as monitor relevant data and requirements. With these functionalities, handling purchases, vehicle inspection records, and managing inventories can become simpler.

Built-in reporting systems

The best preventive maintenance software enables drivers to quickly complete their inspection reports, helping your company maintain regulatory compliance and follow SOPs.

Drivers can use electronic reports built into the software, add comments, and upload photos and inspection results fast.

Fleet managers can then view the report, enabling them to respond instantly to any issues discovered. This also lets them create an easy-to-follow electronic audit trail to support requests for resources and other documents.

Instant maintenance reminders

Excellent truck maintenance software automatically reminds you of upcoming scheduled tune-ups, cleaning, and other upkeep activities based on your predefined metrics.

With automated maintenance reminders, you remain on top of repairs, manage work schedules accordingly, and ensure all fleet vehicles receive appropriate maintenance.

Analytics and insights on maintenance-related

A robust preventive maintenance software can monitor your fleet’s vehicle diagnostics and driving behaviors through GPS systems and other sensory devices.

Fleet managers can use the data and insights they obtain to improve their operations further.

Mobility and web app synchronization

The best preventive maintenance software has a mobile app on top of the dashboard that fleet managers can access through laptops and desktop computers.

This allows drivers to conduct inspections and send reports regardless of their location, as long as they have internet access. Because the mobile app syncs with the web app in real-time, drivers and fleet managers can work easily and cohesively.

User-friendliness

A top-notch truck maintenance software has an intuitive user interface that you and your drivers can learn to navigate easily.

This shortens the onboarding, training, and learning curve and lets drivers use the preventive maintenance software sooner rather than later.

Ideally, the preventive maintenance scheduling software should also be configurable, enabling you to customize your users’ access to data and features.

Why use Motive as your preventive maintenance management software?

If you’re looking for a feature-rich and reliable preventive maintenance scheduling software, try Motive’s proactive maintenance solution.

There are a few ways the Motive fleet management dashboard and integrated maintenance platform can help fleets of all types and sizes by providing detailed reporting and actionable insights.

Motive automatically tracks service needs and notifies you with Maintenance Reminders, helping you stay on top of scheduling to maximize vehicle and asset health.

With customizable DVIRs, fleets can stay compliant and easily define inspection reports that fit their specific needs.

With Motive’s automatic vehicle diagnostics and fault code detection features, you receive instant alerts so you can catch any potential issues and defects early before they become operational hurdles.

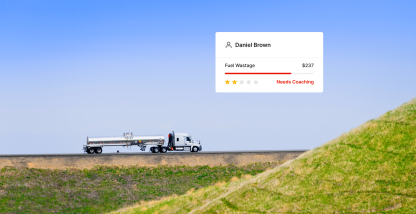

Vehicles in imperfect conditions can also inflate fuel expenditures. Motive’s detailed vehicle utilization reports show how your fleet’s fuel consumption stacks against the network of vehicles using Motive. By benchmarking, you can tell whether your fleet’s fuel consumption needs improvement and take necessary actions if needed.

Last but not least, Motive offers a wide variety of features to help coach drivers improve their driving habits, e.g., hard acceleration, hard cornering, speeding, etc. Improvements in driving behavior not only make your fleet safer but also reduce vehicle wear and tear and increase fuel economy.

Improving drivers’ driving habits can be a part of an effective preventive maintenance management program. That’s because the more responsible the drivers are, the less damage and maintenance work vehicles would require, so you can avoid needless expenditures.

Optimize your preventive maintenance efforts with Motive

Preventive maintenance improves your fleet’s productivity, availability, and profit-generating potential.

However, your routine maintenance tasks won’t be nearly as effective if you aren’t using a feature-rich preventive maintenance management software that helps automate processes and offers customizable solutions that fit your needs.

With Motive, you can kickstart a seamless and well-coordinated preventive maintenance program. Request a free demo to learn how Motive can help you with preventive vehicle maintenance.