Starting today, we’re expanding the Motive Automated Operations Platform to monitor refrigerated fleets beyond Thermo King trailer units.

Reefer fleets today still rely on manual processes to analyze temperature logs, manage trailer uptime, and program trailer refrigeration units. It’s estimated that up to 20% of temperature-controlled freight spoils in transit. The consequences of a poorly maintained and monitored reefer unit extend far beyond monetary losses when compromised cargo like food and drugs can endanger consumer safety.

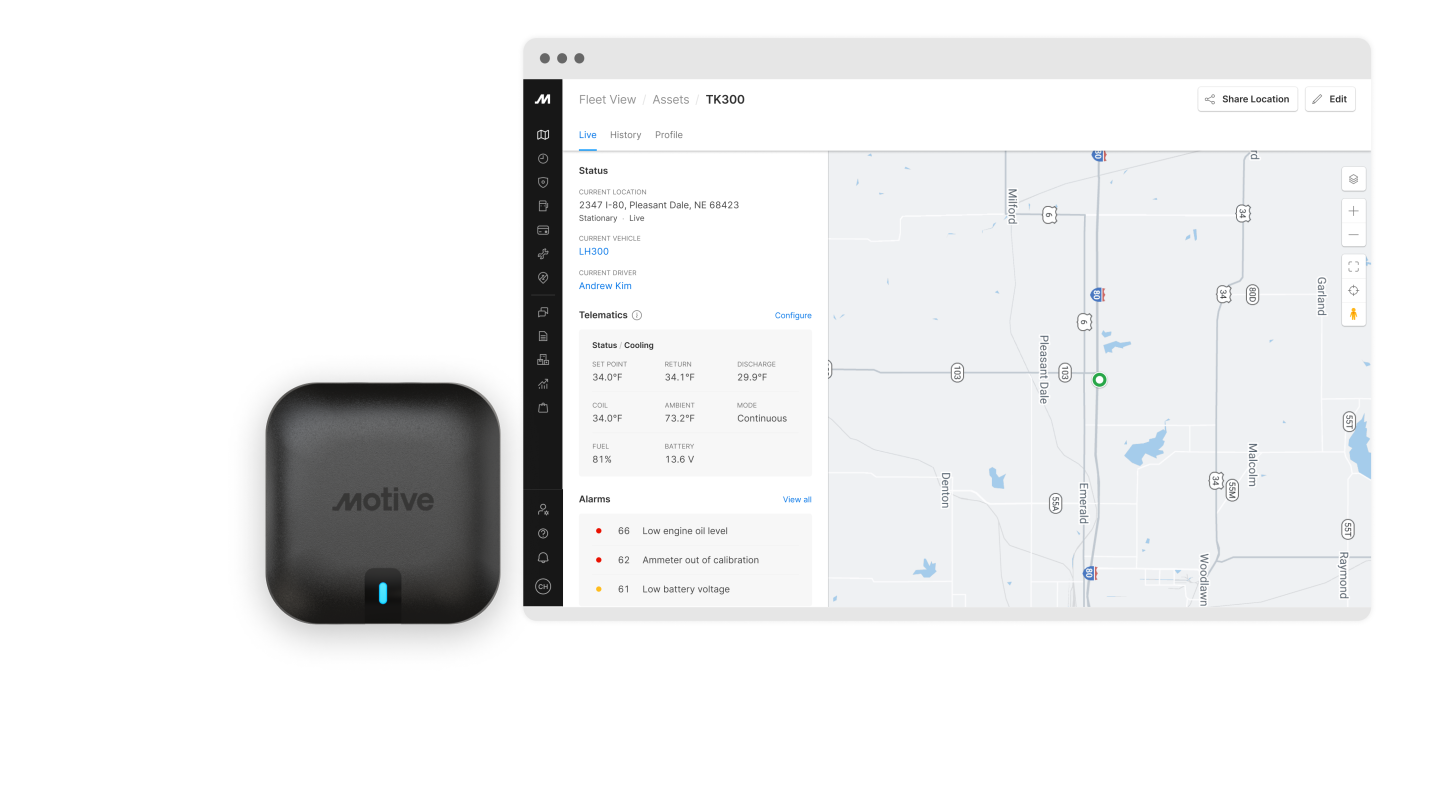

Our new Environmental Sensor remotely monitors the reefer temperature and humidity conditions in real time. In a single dashboard, Motive customers can now automate their reefer management, view reefer telematics, and access temperature logs while eliminating errors and reducing operating costs.

The Reefer Monitoring solution also makes it possible to generate temperature logs from any time period on demand without the need to visit a dealer’s service, which reduces cost, decreases reefer downtime, and improves the service that fleets can provide to their own customers. It also helps fleets to comply with the Food Safety Modernization Act (FSMA) requirements.

Versatile and precise hardware

We designed the Environmental Sensor to be flexible with any cold chain logistics business — including companies transporting food, beverages, crops, flowers, medication, etc. The sensor can be easily mounted on any trailer surface and has a replaceable lithium battery that will last 3–5 years.

Each device contains an internal temperature sensor that captures measurements within +/-0.5ºC (1ºF) accuracy range at a one-minute sample rate, as well as an internal humidity sensor that can measure the relative humidity between 0-95% at a one-minute sample rate. The Environmental Sensor connects to the Motive Asset Gateway Solar via Bluetooth, leveraging cellular connectivity for data transmission to the cloud. Motive customers can create an advanced multi-zone reefer monitoring solution by connecting up to six sensors to one Asset Gateway Solar

“Delivering ice cream at -20°F when it’s 90°F degrees outside requires us paying great attention to the conditions inside our reefers,” said Marc Cain, Transportation Manager at Mayer Bros Apple Products. “Motive Reefer Monitoring enables us to set the report for every 15 minutes to ensure there are no issues with the load. Having this level of visibility saves us 5–10 hours per week in fleet manager productivity and prevents any spoilage.”

Integrated solution

Cold chain logistics is a complex business with high stakes, so it’s important everything performs properly. We’re helping to mitigate food spoilage, increase customer satisfaction, and lower the operating and maintenance costs of trailer reefer units by proactively detecting problems.

By integrating environmental data into the Motive Automated Operations Platform, fleet managers can look at reefer trailer health within the context of their total operations. Other Motive features like dynamic ETAs, geofences, and automated vehicle/trailer pairings set our solution apart from reefer point solutions. With Motive Reefer Monitoring, reefer fleet managers can manage every aspect of their fleet.

At Motive, our mission is to unlock the potential of the physical economy. The Motive Reefer Monitoring solution makes this mission a reality for cold chain logistics companies. By plugging this solution into the Motive Automated Operations Platform, we give our customers complete visibility into their refrigerated cargo.

Motive’s Environmental Sensor and integration with Thermo King are available today to customers in the United States and Canada. Learn more here.