Today’s supply chains are global and require a network of visibility and trust. The complex inner workings of a supply chain can cause valuable information to be lost in the shuffle, instead of utilized to create effective, long-term solutions.

Providing detailed insights to customers can provide an unmatched level of satisfaction. In addition, having a clear understanding of a supply chain’s operations allows for the necessary analysis and process improvements that can lead to cost savings and competitive advantage.

But what is supply chain visibility and how does a company gain a bird’s-eye view into their operations? This detailed blog covers everything you need to do in order to attain end-to-end supply chain visibility.

What is supply chain visibility?

Supply chain visibility (SCV) refers to either the inner workings of a company’s operations or the operations across a partner network. In both scenarios, SCV allows for the ability to track components, sub-components, and final products as they move through the chain while providing near real-time data on supply chain visibility. This data can be used to identify shortages, bottlenecks, trends, and other insights that assist in improving processes.

The goal of SCV is to increase customer satisfaction by becoming more efficient, and reducing risks while, of course, increasing profits. With the learnings gathered from SCV, companies are able to forecast and execute effectively.

What does end-to-end visibility mean?

End-to-end (E2E) visibility refers to offering visibility into every step within the supply chain, from procurement of goods to final delivery. It’s important that these stages are accurately tracked and reported in order to achieve total E2E visibility. The six stages are:

- Procurement and inventory management

- Finance

- Logistics

- Operations

- Quality control

- Sales and customer service

Companies gain actionable insights by monitoring the goods as they move through each stage. With this data, companies can improve their operations and future planning.

How to improve supply chain visibility

Here are some numbers that convey the importance of supply chain visibility data:

According to East West Manufacturing, while transportation accounts for roughly 50% of logistics’ costs, only 9% of logistic professionals have total supply chain visibility. Additionally, over 30% of shippers aren’t familiar with how to acquire valuable data and the opportunities associated with said data.

So how does a company improve supply chain visibility? We’ve put together a comprehensive list based on our research.

Step 1: Know where your supply chain currently stands

It’s important to be fully aware of where your company’s supply chain operations currently stand. Meeting with internal departments and key partners will help develop an understanding of current pain points and gaps. Based on the information gathered, determine the impact on your company. For example, are you experiencing any unnecessary operating costs? How is your customers’ experience diminished? Use this information to create a detailed overview that may highlight any hidden bottlenecks.

Step 2: Envision the future

Based on the detailed overview you’ve gathered, it’s time to set goals. These goals can be related to financial gain, improved company operations, enhancing customer experience, or all of the above. The key here is to set deadlines for each goal established. Begin every step with an end in mind.

Step 3: Invest in solutions

With goals established, the next step is to identify the areas in your existing systems to invest in and identify integrated solutions that will enhance your supply chain visibility. Creating SCV requires sophisticated technology that provides all the data and analysis capabilities that your company needs to track the stages of your supply chain accurately and efficiently.

Additionally, automation is key. Remember that the goal is to track every stage of the supply chain, so remove manual tracking processes where possible to reduce errors and improve efficiency.

Step 4: Analyze the data

Every company should have systems that are capable of measuring key performance indicators (KPIs), and it’s important to measure these results and determine where they land in relation to your goals. Without accurate analysis, all data is useless; what does the data indicate? Are your goals attainable? Do your business practices and goals align? This is where you utilize the data to improve your operations and start reaping the benefits of SCV.

Step 5: Keep a learner’s mindset

It’s important to remember that creating SCV isn’t a one-and-done process. This is a continuous, long-term cycle of improvement. Revisit your business goals and processes and adjust accordingly using the new data as it comes in.

Common supply chain visibility challenges

Supply chain visibility comes with many common challenges, namely lack of planning, disorganization, and data management.

Having limited availability of valuable insights can also cause many challenges. Typically caused by lackluster technology, processing and executing any improvements can feel like a lost cause.

Challenges also come as a result of manual processes. Relying on manual efforts to handle supply chain stages causes gaps and vulnerabilities that innovative automated systems can solve — cost being high up on the list. In 2019 alone, half of U.S. sales (both manufacturing and distribution) were processed manually. That’s about $8.4 trillion business-to-business sales that could have saved companies thousands of hours per year by removing tedious methods and potential risks.

Supply chain visibility solutions

Relying on manual processes when handling supply chain operations is tedious mainly because they pose an increased risk for human error. With that in mind, it’s important to explore which tools can automate processes while providing full supply chain visibility.

Technologies

There are two types of technology that companies are using to improve real-time supply chain visibility. Companies are increasingly using Internet of Things (IoT) technologies as a way to collect data from devices used to monitor, report, and exchange data on supply chains. Over time, IoT technologies have become an effective way to track the movement, storage, and expected delivery of goods.

The second is radio frequency identification (RFID) tags, which have been used as a supply chain tool for some time because of their ability to allow for individual components to be identifiable. This further enables tracking, as the RFID tags are used to count items as they’re packaged and en route.

Analytics

Detailed, advanced analytics provide the in-depth data needed to assess and improve supply chain management and visibility. Analytics can be used to determine where a company’s supply chain operations fall short. Advanced analytics can also be used to develop proactive strategies and solutions for the future.

For example, descriptive analytics utilize historical data and summarize this information in an organized fashion. Diagnostic analytics, however, provide specific insights into the “why” behind challenges in supply chain operations.

With the use of AI and mathematical algorithms, supply chain analytics can be implemented to utilize the above-gathered data and predict any future problems that may arise — this is what we call predictive analysis.

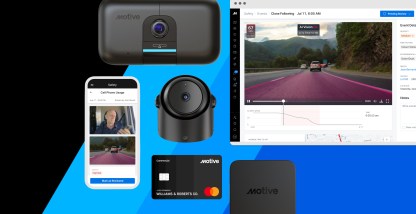

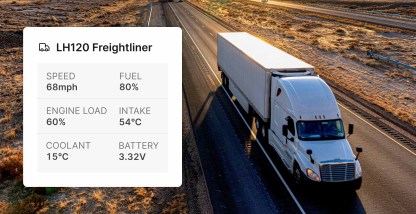

How Motive can help with your supply chain visibility

Smooth total supply chain visibility, both internally and externally, is essential to business survival. Our integrated fleet management platform ensures driver safety, workflow management, and ELD compliance, all while providing the ability to track and manage your supply chain thoroughly and efficiently.

To learn more about how Motive can be your supply chain visibility solution, request a free demo today.