Equipment failure

Additionally, equipment failures can cause severe damage to perishable goods.

Common challenges

Frequent malfunctions include fluid leaks, faulty belts and hoses, faulty calibration, damaged air chutes, condenser issues, sensor malfunctions, damaged door seals, and bulkhead blockage.

In short, there is plenty of opportunity for cargo on a reefer to be destroyed.

Solutions

Again, while it’s important to conduct maintenance inspections on the equipment, it’s more important to be aware when something is no longer operating as intended.

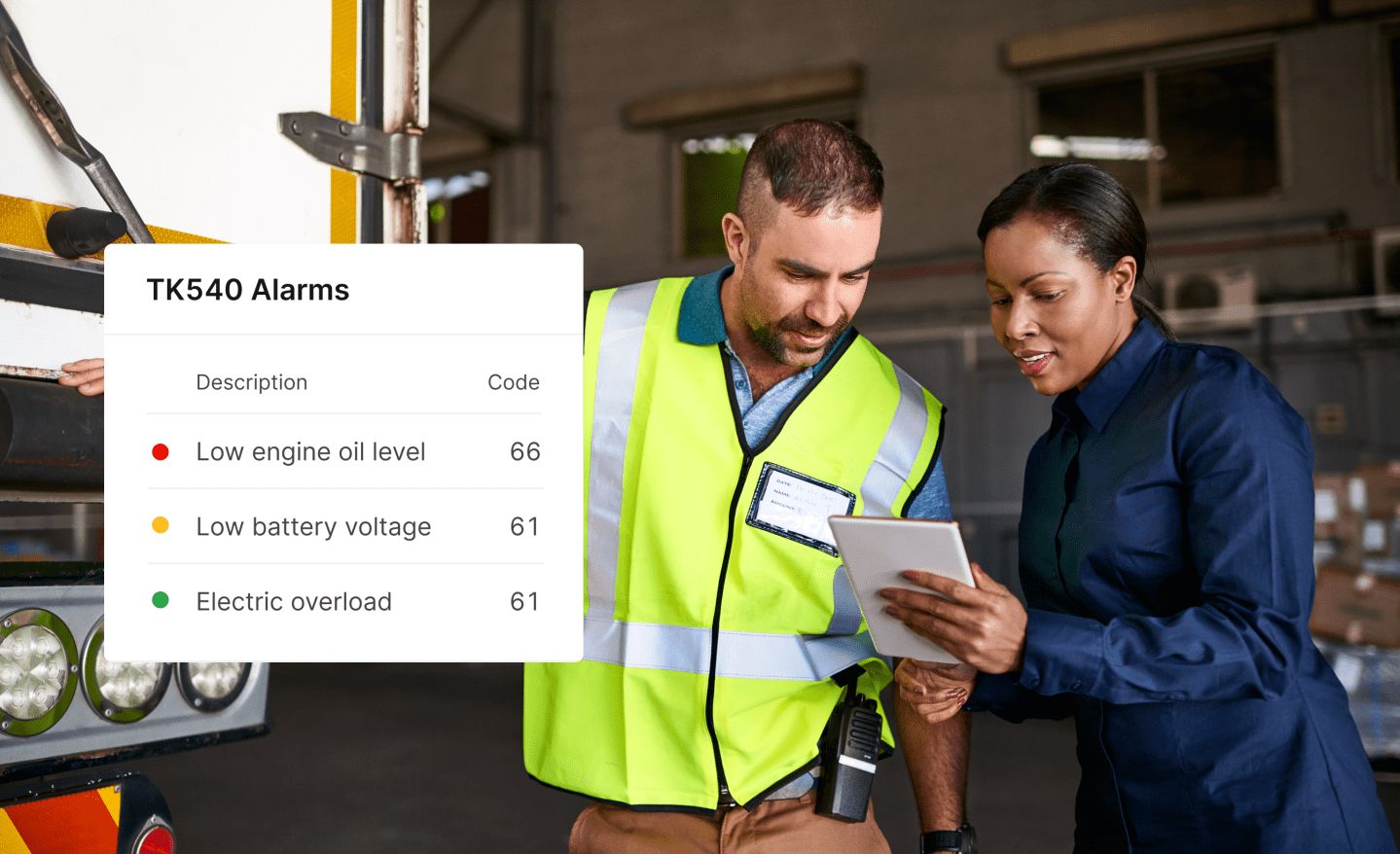

Thermo King integration

Thermo King’s products provide 250 alarm codes, all designed to capture any faulty equipment immediately, before any damage is done.

Motive’s Thermo King integration pulls telematics data into the dashboard to help fleet managers make informed decisions when it comes to reefer management. For example, if a reefer is on the road, drivers and managers can actively monitor the status by viewing it on the Fleet Dashboard, or be notified if the reefer is outside of the desired temperature.

Proactive alerts

Proactive alarms and alerts are another way to minimize the impact of reefer equipment failures.

Fleet managers and drivers can set specific alarms with customized conditions to help stay ahead of any potential risks. These alerts can be created with specific ranges, entity types, and “trigger ranges,” based on the individual’s need.

With Motive’s Fleet Dashboard, drivers can review historical alerts before getting on the road, to make sure all systems are “go.”