You may not be in the habit of thinking too deeply about tire tread depth. Yet tread depth for commercial vehicles can have a real impact on fleet safety and success. This informative guide shares how to check tire tread depth and other tips for commercial drivers and fleet safety managers.

What is tread depth?

Tread depth refers to a vertical measurement from the top of tire rubber to the bottom of the tire’s groove. The depth in the United States is measured in 1/32 of an inch. Millimeters will be used in countries using metric.

Tire tread depth impacts grip on the road. It also affects acceleration and braking capability and can influence fuel economy. Any wear on tire treads can hinder vehicle performance.

Tire treads typically come in symmetric, directional, or asymmetric patterns. Overall, tire tread has up to five main components. They include

- Ribs: the long, raised band around the tire

- Blocks or lugs: raised segments between the ribs

- Grooves: space between ribs

- Voids: space between tread blocks

- Sipes: thin slits cut across the tread blocks and ribs

Why is it important to check tire tread depth on trucks?

In an annual Commercial Vehicle Safety Alliance (CVSA) Roadcheck blitz, “19% of the 11,910 vehicles placed out of service had received tire and wheel violations.”

Effective tire maintenance can make a big difference for a commercial fleet. Tire maintenance helps fleets avoid vehicle performance issues and maximize profitability.

A worn tire tread can be dangerous in challenging driving conditions. It’s especially problematic for commercial vehicles driving in rain or snow. Heavy wear of the truck tire tread can cause a tire blowout. In 2019, according to the NHTSA, 612 fatalities were attributed to tire-related crashes.

Tire tread depth evaluation can also relay important information about the asset. Firestone notes the points below.

- Excessive wear in the center tread indicates overinflation.

- Excessive wear on shoulders could signal underinflation.

- Excessive wear on one tire side signals incorrect camber angle (related to steering and suspension).

- Knobby treads on the outer section can signal problems with the toe-in value. It can impact steering stability.

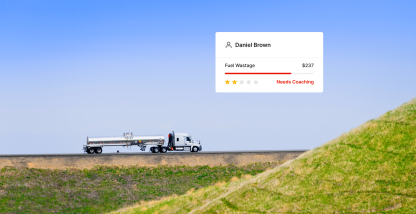

Motive’s AI-powered fuel and maintenance management solution helps fleets save up to 10% on annual fuel costs. It also sends maintenance reminders. Fleets can track service history and schedule notifications to stay current on tire tread depth and other asset checks.

What are tread depth regulations for commercial trucks?

Tread depth for commercial vehicles is subject to federal and industry regulations. For the Federal Motor Carrier Safety Administration (FMCSA), minimum tread depth for truck tires needs to meet § 393.75:

- Steer tires, or any tire on the front wheels, must have a minimum depth of tread of 4/32 of an inch.

- Every other tire must have a minimum depth of 2/32 of an inch.

These Department of Transportation (DOT) truck tire tread depth regulations are more stringent than regulations set by the CVSA, outlined below.

- Steer tires must have a minimum depth of tread of 2/32 of an inch.

- Every other tire has to have a minimum depth of 1/32 of an inch.

In a comprehensive North American Standard Inspection, the safety inspector will examine the suspension, tire, rim, hub, and wheel assemblies. But tires make the list of items checked at most levels of roadside inspection.

Ensure vehicle safety across the fleet with customizable commercial vehicle inspections from Motive. You can define the parts the drivers need to inspect based on the vehicle type. You can also give inspection instructions for each part.

How to measure commercial truck tire tread depth

A tire tread depth gauge is the most accurate tool. Some light truck, commercial, and performance tires come with tread wear indicator bars. Embedded between the ribs of the tread at 2/32 of an inch, these let you see if the tread is flush with the indicator bar.

You can measure truck tire depth against a commercial truck tire tread depth chart. Different commercial trucks will have varied original tread depths.

Tread depth information may help answer the question “which tires are best for my fleet?” Manufacturers have developed application-specific tires to deliver operational savings and performance gains. Truck tire depth can be a factor. For example, as trailer leasing company Boxwheel notes, “For long hauls, it’s important to have tires that deliver extended wear and that have low rolling resistance. If your driving is primarily local, thicker tread and specially designed sidewalls can help protect a tire from the additional puncture hazards and issues like ‘curbing.’”

Can you buy a tire tread depth gauge?

Yes, you can find one easily online or at an auto parts store. Manual and digital options exist, as well as plastic or metal devices. Some come with a tire pressure gauge. You can use the probe to measure the depth from the topmost rubber of the shallowest groove on the tire.

What to do if your truck tire treads are uneven

Don’t disregard uneven truck tire treads. If tires are mismatched, the tire with deeper tread will carry more of the truck’s burden. It can wear down that tire prematurely and put uneven pressure on the suspension.

Irregular tire tread depth can mean the vehicle alignment is off. That could result in tires needing to be removed sooner than planned and indicate other asset problems.

Truck tread depth can signal truck mechanical issues. Such as “a bent axle, damaged tie rod, worn out ball joint, broken suspension component, or loose wheel bearing.”

When you’ve examined truck tire tread depth and found the tread depth to be uneven, you’ll need to take action. Depending on the extent of the tread wear, you may be able to rotate the tires. Otherwise, remove them to ensure driver safety on the road. Retreading is another option.

Get more driving safety tips to keep fleet drivers safe on the road.

How to measure tire depth on commercial vehicles

You don’t want to focus exclusively on truck tire depth. Your fleet may have other vehicle assets whose tire treads need to be monitored for appropriate tire tread depth.

Agricultural or construction vehicle tires may require deeper treads for traction in tough conditions. It often depends on the surfaces you’ll be driving on. You’ll still be using a tire gauge measuring 1/32 of an inch to stay on top of tread depth.

What is the penny test?

Of course, an actual gauge is a far more accurate tread wear indicator. But if you don’t have a tire tread depth gauge, you can use a standard penny. Use the coin as you would the gauge probe, placing Lincoln’s head upside down in the shallowest groove. If you can see all of Lincoln’s head, you have less than 2/32 of an inch of tread depth left. Turn the penny around and place the Lincoln Memorial upside down. If you can see all of the memorial, you have 6/32 of an inch or more tread depth left.

How to keep your fleet in check with Motive’s safety platform

Accurately measuring tire tread depth and pressure while regularly rotating tires has a positive impact on commercial fleet operations. So does monitoring alignment. Monitoring your driver’s aggressive and risky practices can also help with overall tire health and optimizing vehicle performance.

With the tools to minimize hard braking, hard cornering, and hard acceleration, you can reduce excessive wear on tire treads as well. Motive’s vehicle diagnostic solution is just one part of our fleet safety solution. Proactively monitor driving behavior to detect issues and identify drivers who could benefit from coaching or more training. Learn more today about how the Motive Fleet Dashboard helps you stay on top of vehicle health and prolong the life of commercial vehicle tires.