Construction fleet tracking describes the process of monitoring and managing the movement of vehicles that transport materials to and from a job site, haul heavy equipment, or deliver supplies. A tracking system gives construction companies real-time visibility into trucks, equipment, and personnel. Fleet tracking can also enable them to optimize their operations, improve efficiency, and reduce costs.

Many construction trucks and heavy equipment come equipped with GPS technology and other tracking devices that support monitoring of their location, speed, and other important metrics. By monitoring GPS data, construction companies can ensure that their vehicles and equipment are used efficiently and not sitting idle, which can result in wasted resources and lost profits.

This allows companies to streamline their operations, reduce fuel consumption, and increase productivity. Companies can also leverage fleet tracking to identify potential hazards and take necessary precautions to prevent accidents and injuries.

Frequently Asked Questions

How are fleet vehicles tracked?

Fleets are tracked using GPS devices installed in the vehicles, which transmit location data to a central monitoring system. Fleet managers can use the data to locate and track vehicle movements in real-time. This helps ensure efficient routing and scheduling. GPS tracking also provides valuable data on vehicle usage, maintenance needs, and driver behavior, allowing for better fleet management and cost savings.

What is fleet tracking?

Fleet tracking is the process of monitoring and managing a fleet of vehicles or assets using GPS or other tracking technologies. Tracking devices are installed in vehicles or heavy equipment used in the construction industry to help companies collect real-time location data, speed, and other relevant information. This enables businesses to track the movement and performance of their fleet, optimize routing and scheduling, monitor driver behavior, improve fuel efficiency, enhance security, and streamline overall fleet management processes.

How much is a fleet tracker?

The cost of a fleet tracker varies depending on the features and capabilities of the device. Basic models can start around $50 per unit, while more advanced models with real-time tracking and advanced reporting can cost several hundred dollars per unit. Additionally, there may be subscription fees or other costs associated with the use of fleet tracking software.

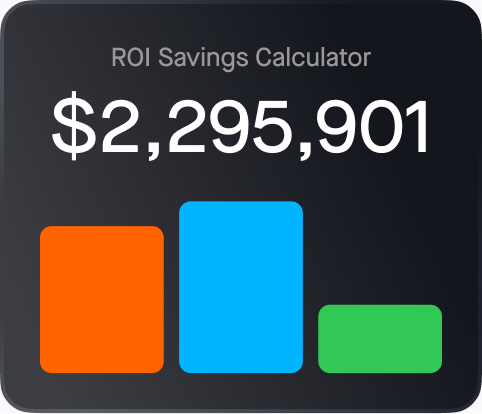

When weighing the cost of a fleet tracking system, consider the return on investment. Fleet tracking can lead to increased efficiency, productivity, and profitability. Integrated software helps collect data, generate reports, optimize routes, and manage ETAs, which helps companies make informed decisions.

Do fleet vehicles have tracking devices?

Yes, fleet vehicles generally have tracking devices installed. These devices use GPS technology and telematics to track the location, speed, and other important data related to the vehicle. This helps companies ensure safety, efficiency, and compliance with regulations. Fleet tracking systems also provide valuable insights into driver behavior, vehicle maintenance requirements, and fuel consumption, enabling companies to make informed decisions and optimize their operations.