Recently, consumer preferences shifted dramatically from shopping at local brick-and-mortar retailers to online with on-demand delivery. With this shift in consumer behavior, the demand for reefer trailers and cold chain management has also increased to keep pace with market demand for temperature-sensitive products. The companies that transport temperature-sensitive products must adhere to precise temperature controls to ensure product quality and Food Safety Modernization Act (FSMA) compliance.

The new Motive and Thermo King integration automates reefer management, allowing customers to get full visibility and stay compliant while eliminating errors and reducing operating costs.

Understanding cold chain management

Cold chain management is the process of shipping, storing, and displaying temperature-sensitive goods for various industries, including food and beverage, agriculture, and pharmaceuticals.

Temperature-sensitive products rely on cold chain management for product safety, and adherence to regulatory requirements, like the Food Safety Modernization Act (FSMA). Cold chain management is an essential component of the supply chain to maintain temperature ranges and air quality, including carbon dioxide, humidity, and oxygen levels.

Any disruption or failure within the management process or during cold chain transportation, including processing, storage, and display may cause product spoilage, loss, and financial implications. So maintaining the correct temperature and product environment is critical for everyone involved, from the manufacturer to the shipper and the customer.

Trailer temperature monitoring is essential to ensure quality goods, on-time deliveries, and food safety. Yet, manually managing refrigerated trailers slows down productivity and increases the risk of operator error and spoilage. Centralized reefer monitoring and a remote reefer monitoring system are essential to staying compliant and reducing mistakes.

Motive and Thermo King partner for complete cold chain visibility and control

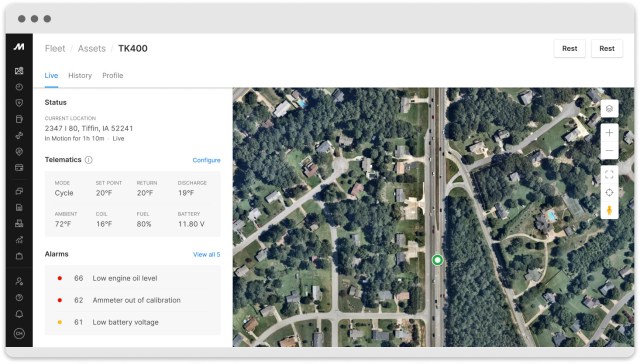

The Thermo King integration decreases programming errors and reduces operations costs by displaying Thermo King refrigeration data, including temperature modes, reefer temperature logs, and alerts in the Fleet Dashboard. The integration requires the new Thermo King cable that connects the Thermo King unit with a Motive Asset Gateway, which handles the connectivity into the cloud.

By connecting their reefer units to the Motive Automated Operations Platform, fleet managers can now conduct reefer temperature monitoring directly on the Fleet Dashboard along with the other fleet telematics. They can dive into historical temperature and telematics data and set alerts for when temperature conditions fall out of a specified range during cold chain transportation.

Not only can fleet managers monitor their reefer units, they can also control them directly from the Fleet Dashboard. With this remote reefer monitoring system, fleet managers can set the temperature, eliminating the need for the driver to wake up to start the pre-cooling process hours before departure.

Finally, to produce a reefer temperature log for their customer or an FSMA audit, fleet managers no longer have to take the reefer to a dealer, removing the trailer from active use. Instead, they can produce the reefer temperature log right in the Fleet View.

Real risk prevention

For our partners who participated in our product testing program, having real-time and accurate reefer temperature telematics was a game changer for their day-to-day operations. The remote reefer monitoring system changed how a reefer was pre-cooled. Reefer tracking and telematics helped them decide which reefer needed maintenance. When a load was on the road, drivers and managers could actively monitor reefer temperatures and status by viewing them on the Fleet Dashboard or set up automatic notifications to be sent when a reefer is outside the desired temperature range. These features helped companies better understand their risk and actively manage their reefers for higher efficiency and lower load spoilage.

Get started

Motive Reefer Monitoring is available now for customers equipped with Motive Asset Gateways in their Thermo King reefers. Learn how we can help you connect and automate all aspects of physical operations. Get more information about Motive solutions.