There’s nothing more frustrating than losing precious time, money, and resources when a job stops because equipment is not delivered on time, breaks down unexpectedly, sits idle, or is stolen. The negative impact due to a lack of visibility and real-time tracking of equipment and assets is a major issue across industries, from construction and energy to field services and logistics.

According to Levelset’s National Construction Payment Report, 66% of construction professionals say they spend more than a quarter of their work hours waiting for work to be done, often because they are waiting for tools and equipment. Equipment theft costs the construction industry as much as $1 billion annually, according to the National Equipment Register (NER).

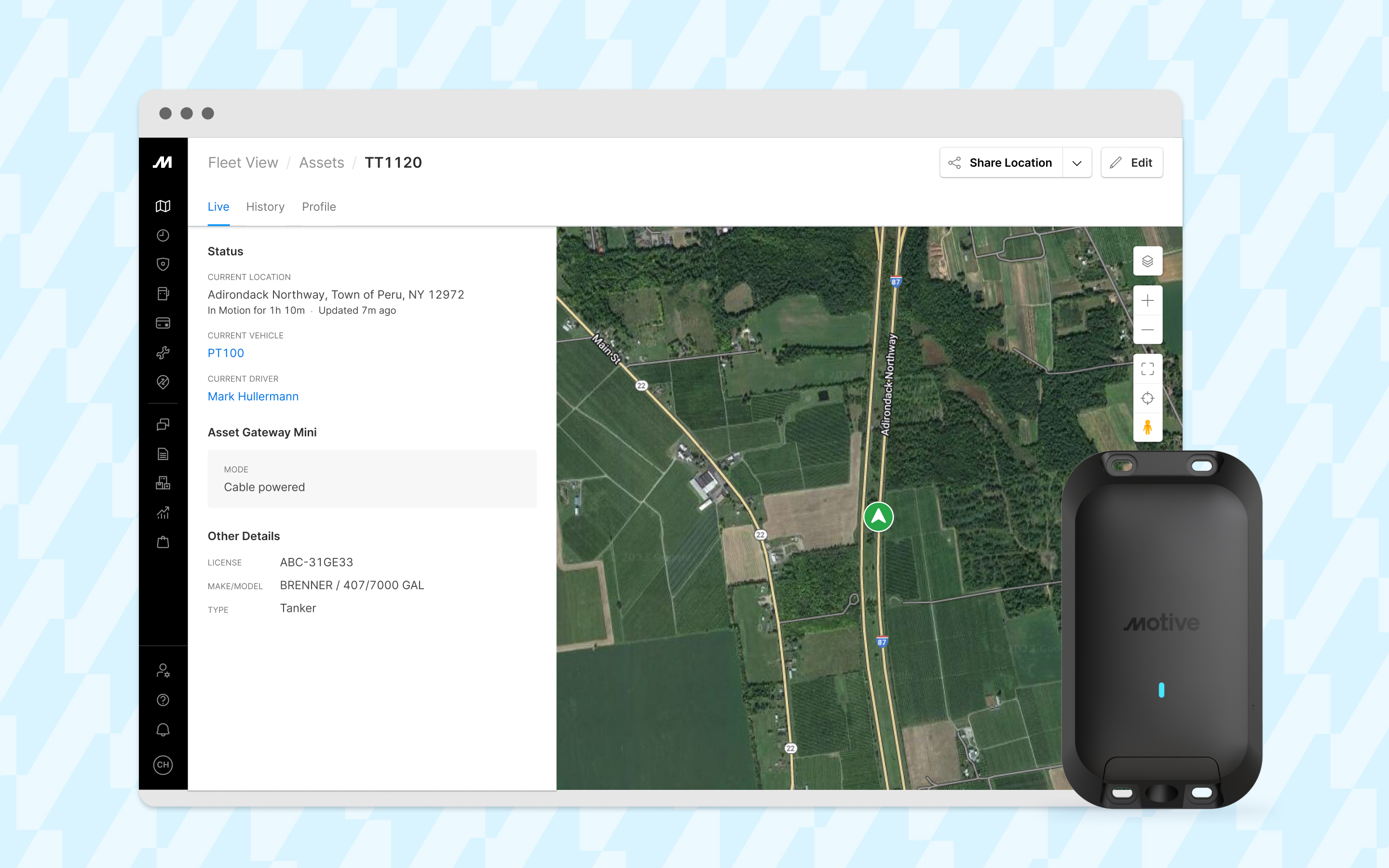

Instead of living with frustrating tracking issues, you can finally know where every asset you own is right now with the new Motive Asset Gateway Mini. Measuring just 5.8 inches long and 3.3 inches wide, its compact design is versatile and discreet, enabling you to track the location, utilization, and health of all your equipment in a single integrated platform. Whether it’s powered machinery like excavators and forklifts or smaller unpowered items like portable toilets and toolboxes, you gain unparalleled visibility and control.

“We were frustrated with the connectivity issues we experienced with our previous asset monitoring system,” said Eduardo Lopez, Loss Prevention Representative at E&A Welding. “Since switching to the Motive Asset Gateway Mini, we’ve seamlessly tracked a range of assets without issue, from climate-controlled trailers to generators, even equipment without an internal battery.”

Eliminate manual check-ins, reposition underused assets, prevent theft and loss, and minimize equipment downtime by keeping every piece of equipment visible and accessible.

Maximize utilization, minimize downtime

The Asset Gateway Mini provides unique cable- and battery-powered options in a single device, ideal for companies who need occasional location updates for high-volume inventories, where cabling isn’t an option. The battery lasts for five years at two GPS pings per day. And for real-time visibility, you can cable in assets to gain insights into location and telematics, providing utilization insights that enable the repositioning of underused assets and automated client billing.

Fleet managers can easily track inventory within specific geographical boundaries, while real-time preventive maintenance alerts notify managers which equipment is due for scheduled maintenance to help avoid more expensive repairs.

“Our existing asset trackers were failing on just about everything,” said Brian Cooper, Fleet Manager at Preston Landscape Services. “I finally had enough and made the leap to the Motive Asset Gateway Mini, which is perfect to tuck into our smaller skid steers, trenchers, tractor mowers, and more. Its discreet size and unpowered mode mean we can easily track each equipment’s location and engine hours, saving us valuable time and boosting utilization. The automatic vehicle asset pairing will also ensure the right equipment is delivered to the right job site.”

Reduce theft and loss

The compact size of the Asset Gateway Mini enhances its security, making it harder for thieves to find and remove. Real-time geofence alerts provide immediate insights into unexpected asset movements, which are critical to fast-tracking the search for stolen or missing equipment. Locate My Asset, coming in early 2024, helps you instantly locate missing assets and plan for capacity with on-demand location requests.

“Having had equipment worth $25,000 stolen in the past, the ability to immediately locate any missing asset is invaluable for our peace of mind and security,” said Lopez.

Designed in-house by Motive’s product engineering team, the Asset Gateway Mini comes with a five-year warranty and was built to perform in harsh conditions. Devices undergo stringent testing and quality controls, covering everything from extreme temperature ranges, gravel bombardment, and high-pressure water sprays.

End-to-end visibility

The journey to full operational control doesn’t stop here. Our AEMP 2.0 integrations with leading original equipment manufacturers (OEMs) like Caterpillar, John Deere, Komatsu, and Volvo help companies manage all of their heavy equipment from different manufacturers on one platform. For example, construction managers can stay on top of a bulldozer’s downtime and a crane’s engine hours to optimize utilization and pre-empt potential mechanical breakdowns.

Motive’s Reefer Monitoring solution provides you with precise temperature and humidity monitoring through our Environmental Sensor and accessible temperature logs for FSMA compliance. Fleets with Thermo King units can remotely control and monitor their reefers through the Motive Dashboard. Get alerts when reefer temperatures spike near critical levels or Thermo King fault codes are detected.

“Industrial enterprises operating in the physical economy with equipment and people distributed across geographies face many challenges when it comes to efficiently monitoring the location and use of their valuable assets,” said Mark Fontecchio, research analyst at 451 Research, part of S&P Global Market Intelligence. “To address these challenges, companies are increasingly deploying IoT technologies across their operations to improve efficiency, mitigate risk, and lower costs. And, the trend will continue as the performance and capabilities of IoT technologies continue to address these compelling use cases.”

Ready to stay on track with Motive Equipment Monitoring?

With the addition of Asset Gateway Mini, Motive’s comprehensive Equipment Monitoring solution empowers the people who run physical operations with unparalleled visibility and control of the equipment their teams depend on every day. From powered and unpowered equipment to trailer and reefer monitoring, we offer a solution for every use case.

Deploying field-tested hardware that’s fully integrated with the Motive Integrated Operations Platform allows you to take the next step in making your work safer, more productive, and more profitable. Motive Equipment Monitoring is part of an integrated platform that includes Fleet Management, Driver Safety, and Spend Management so your team can get greater visibility, more control, and simplify tasks.

Experience it firsthand by requesting a demo. Also, reserve your spot today for an in-depth live Equipment Monitoring webinar on November 29.