Although ELDs were introduced to enforce hours-of-service compliance, these devices offer much more than that. Electronic logging devices provide valuable data and insights into a fleet’s operations. Fleet managers can use that ELD data to boost efficiency, reduce operational costs, and increase profitability.

Following are five ways you can use ELD data to minimize cost and increase profit.

1. Increase efficiency with vehicle utilization

Better vehicle utilization equals higher profitability.

Since an electronic logging device is connected to the engine of the vehicle, it can automatically record excessive idling and present that information in the web dashboard.

Research from the Department of Energy shows that the trucking industry wastes 6 billion gallons of fuel due to idling. Not only can idling negatively impact carriers’ revenues, it is an irresponsible practice that also results in exhaust emissions that harm the environment.

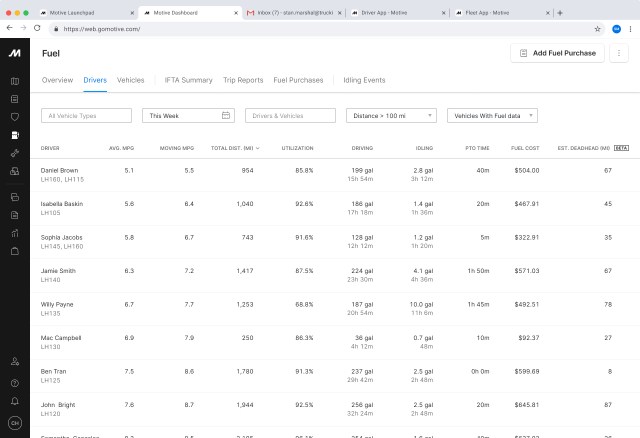

The Motive ELD has a robust idle time tracking feature that allows fleet managers to identify drivers who idle for too long or too frequently. They can also view the vehicle utilization rates for the entire fleet or break it down by vehicle, driver, or terminal groups.

Motive also tracks start time, duration, location, and fuel consumed. By using this data, fleet managers can quickly identify drivers who require coaching.

Improving vehicle utilization and putting a stop to idling can significantly improve the bottom line of the company.

2. Improve safety with driver safety scores

ELDs can also give you valuable insights into how safe your drivers are.

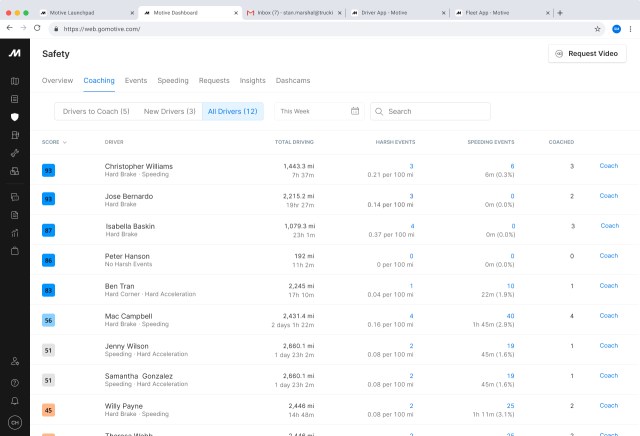

For instance, the Motive ELD monitors poor driving practices and detects critical safety events, such as hard braking, hard acceleration, and hard cornering. Safety scores are then calculated for each driver in the fleet.

This data allows fleet managers to quickly identify and coach high-risk drivers. Which reduces the likelihood of accidents and liabilities and improves the overall safety of the fleet.

A safer fleet means fewer accidents and lawsuits, a better CSA score, more business opportunities, and higher profits.

3. Use GPS data to win detention time disputes

According to the Department of Transportation, detention time disputes cost carriers between $250.6 million to $302.9 million annually.

Detention time pertains to situations in which the driver is delayed at the point of pickup or delivery for more than the normal timeframe. Detention may cause the driver to lose legal driving hours, miss the next load, and lose revenue.

With electronic logging devices, fleets can have complete visibility. Because ELDs have built-in GPS tracking, fleet managers can easily monitor every activity, including when a driver reached their destination. With the help of breadcrumbs and location history, carriers and drivers are in a much better position to win detention time disputes. With real-time GPS and hours-of-service visibility, fleet managers can also plan trips more effectively. Which leads to reduced operational costs and higher profits.

4. Higher driver retention rates

As mentioned earlier, Motive provides detailed insights and reports on driver performance and safety scores. Fleet managers can use this data to structure a performance-based reward system that incentivizes and encourages safe driving as well as improves driver happiness and driver retention rates.

In addition to monetary rewards, companies can also use other motivational techniques. Like formal recognition, trucker of the month programs, gift cards, and extra vacation days to increase driver motivation and driver happiness.

With performance-based compensation and rewards, companies can keep the driver turnout rate in check. Which is extremely important now that driver shortage has officially become the biggest problem in the trucking industry.

5. Proactive vehicle maintenance

With the help of a capable electronic logging device, fleets can also improve vehicle maintenance and catch potential issues before they become major problems.

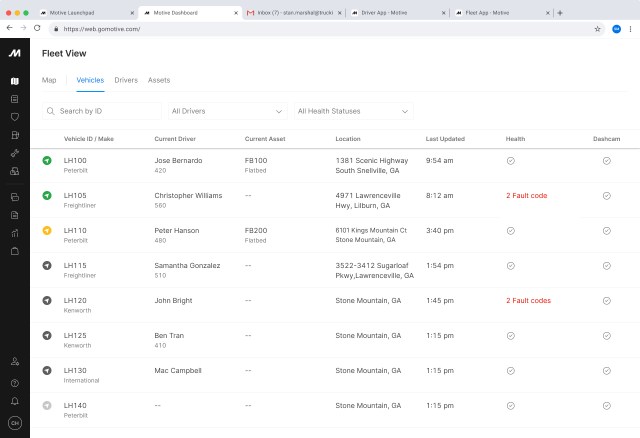

A feature-rich electronic logging device, such as the Motive ELD solution, can automatically monitor fault codes through its direct connection to on-board vehicle diagnostics.

By looking into previous data and historical fault code reports, you can identify recurring issues that need the most attention. The Motive ELD solution automatically flags recurring solutions so you can catch important issues faster.

What’s next?

While ELDs are primarily for compliance with the ELD mandate, smart fleet managers are using ELD data to improve fleet operations, reduce administrative burden, increase effectiveness, and earn more profit.

Jai Ranganathan, Motive’s VP of Product, recently talked about the future of ELDs and how these devices are a gateway to many more capabilities, such as asset tracking, vehicle utilization, and third-party integrations. You can listen to the podcast here.