On-demand webinar

Intro to Motive Reefer Monitoring.

Everything you need to know about Motive Reefer Monitoring

Duration: 1hr

Webinar Details

Learn how Motive Reefer Monitoring improves the compliance, profitability, and productivity of businesses by centralizing the management of reefer trailer fleets.

Integrate directly with your Thermo King refrigerated units and/or install the Motive Environmental Sensor for a multi-point monitoring of your reefer trailers.

We’ll discuss how you can access your temperature logs, live follow your reefer trailers, and set alerts in the Motive Fleet dashboard.

You’ll learn more about:

- Simplifying FSMA compliance

- Lowering Reefer costs

- Using remote reefer control

Speakers

Transcript

Hi, this is Intro to Reefer Monitoring, to Motive Reefer Monitoring. The strongest link in your cold chain today. We’ll be covering some challenges in the cold chain industry. Oh yeah, first of all, the speakers. Yeah, me, Todd, senior product marketing manager here at Motive. And then you have David Chao who’s our senior product manager who has worked extensively on the Motive Reefer Monitoring product

View More

0:00 | Todd Burch

Hi, this is Intro to Reefer Monitoring, to Motive Reefer Monitoring. The strongest link in your cold chain today. We’ll be covering some challenges in the cold chain industry. Oh yeah, first of all, the speakers. Yeah, me, Todd, senior product marketing manager here at Motive. And then you have David Chao who’s our senior product manager who has worked extensively on the Motive Reefer Monitoring product.

We’re excited today to cover some kinds of challenges that we’re seeing in the industry. , that’s helped us shape how we built. Our product will go through why we think we have the best Reefer Monitoring solution for your needs and will showcase a customer story. And then we’ll walk through a live demo of our offering.

We also have a few polls that we’re going to start publishing in this webinar. We want to get to know a little bit more about those that are with us today … their Reefer Monitoring solution. What does your fleet look like? So we can better shape this webinar.

I would say that to start off, I don’t think anyone would dispute that we’re in the digital age of logistics. With all the hardware and software that’s out there to help you manage your fleet, you really have a lot to choose from. We know the cold chain industry has a little bit more complexities than just your regular dry van or other types of freight.

And we’ve noticed that with the increase in FISMA requirements and compliance with the FDA and the Food Safety Modernization Act, there’s a lot more nuances to how you manage your business. And so a lot of companies struggle with accessing and storing temperature logs to meet those requirements and also to provide a certain level of customer service.

We also know that in the cold chain industry, like reefer trailers, there’s an added level of complexity that kind of makes people shy away from this business or also add some difficulties to your day-to-day. We know that the trailers are more expensive. You have requirements like temperature requirements that you must maintain. It just makes running and carrying this type of freight a little bit more complex than other industries.

And then we also know that today a lot of this is dependent on a lot of the success of a temperature-controlled load is dependent on the driver. The driver has to be able to program the TRU properly, they must monitor it as they’re driving down the road, and then they also have to deliver with best practices.

So, with Motive, we were aiming to kind of address these needs. Our mission is to unlock the potential of the cold chain industry and — through our Reefer Monitoring solution — we aim to mitigate food spoilage, increase your customer satisfaction, and lower the operating maintenance costs of trailer reefer units by using data to detect problems proactively.

In addition, with our Thermo King integration, we give you the capabilities of remotely controlling your units and help you to reduce the potential of human error.

I’m going to hand it over to David for a minute to talk about our products.

3:46 | David Chao

So yeah, Motive has kind of tackled this problem from a whole ecosystem perspective. We understand there’s a large range of different reefer units in the field of different makes and models, and we want to try and supply a solution for every customer out there depending on your need. And the first one up here is the Environmental Sensor.

Here at Motive, we pride ourselves in designing our own products. We pride ourselves in working extensively with our engineering and quality teams to make sure that our products are of quality and rigorously tested so they can withstand real-life scenarios in the field. And the first one up here is Environmental Sensor. It is one of these really small … we call airpod-shaped devices — you can see my screen, it’s very, very small.

What these do, these go inside the trailers. You can mount them inside — we recommend near the ceiling of your trailer so that it doesn’t get hit with pallets in daily operations. And, as the image implies, this is connected via Bluetooth —very similar to how your headphones operate via Bluetooth — to your Asset Gateway which tracks all your location telematics.

What this will do is that it will upload once every minute temperature and humidity data that’s within that specific region or location within the trailers to your Asset Gateway which will then show that and store that information and send it to the required dashboard. So what happens is After that data is collected then we’ll have that information stored on our servers and display on your dashboard for you to visualize.

So this, from the last three years on one replaceable coin-cell battery operates between negative 40°C, 85°C. So it operates within a large range of environments. We tested that rigorously with large different types of loads from ice cream to eggs to flowers too. frozen pizzas and a lot of others just to make sure that it works. The other one that we also worked on is directly related to Thermo King.

What Todd was alluding to, this Thermo King integration works as the name implies: only with Thermo King. Our carrier solution will come out in the future. But if you wanted some more actionable actions, in a sense this device here in our hands only senses and displays information and alerts you. If any temperature fluctuations happen with the Thermo integration which is with a cable to this Asset Gateway, we are able to not only gather information that the Thermo King unit is providing, which is a set point discharge, air return, air coil, temperature, remaining battery, and fuel levels within the reefer. We can also allow you to remotely control the temperature and turn on and off, for example, off from our dashboard. So for example, if you were a company or a person who is actually very active in your operation supports you to manage things remotely.

A scenario that could happen is out in the field. You can turn on your reefer on and off when it’s pre-cooling to allow it to get the lower temperature to put in your load. As it pulls away, you notice that something’s happening, you can actually get notified and you can go in yourself to change the set point or change the mode from continuous to cycle century for example, to the correct method that you and your load would support.

So that’s the Thermo King integration right here and there’s a lot of power that comes along with this specific hardware device that we created here at Motive. So what that all means is that, all of this will show up on your dashboard, as I was talking to right? We want to ensure that this information is easily accessible to everyone that has access to the free dashboard.

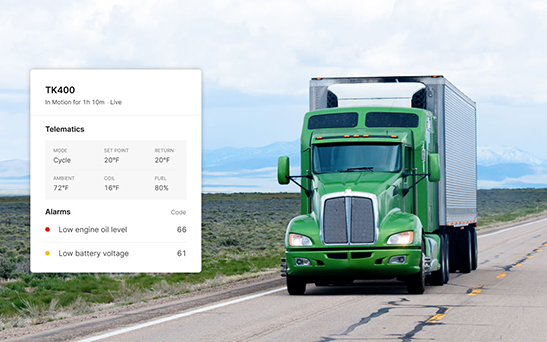

So we’ll walk you through a user journey right here. So the first thing that you can see if you have this integration solution enabled whether it’s with the sensor or with the cable, you would be able to see right off the bat on your dashboard and we’ll demo shortly thereafter a snapshot view of what the temperature looks like. It’s a snowflake icon that you see on the image on the right.

You hover over a reefer and you’ll be able to see what the temperature is through that Thermo King cable or through the Environmental Sensor that you’re using. For example, if you want a little bit more information, you think that something might be wrong. For example, then you can click into your asset very similar to what you do with vehicles or any other assets that you may want to look a little bit more into.

You can click into it and see exactly what temperature and where that location is, where the sensor is located that might be deviating from what you’re expecting. Now, if you’re on the Thermo King platform, like I was alluding to, you have one additional action if you think that something is wrong and you want to fix it, you’re able to actually go into the dashboard, click into it, change the set point or turn it off in an office and a reefer, for example, to actually allow you to change and correct the action right there in your dashboard.

Otherwise, on this platform, the environmental platform will alert, you will send you alerts to you and your driver for example, and that way they can go out and fix the problem right away without having to, look at the light in the rearview mirror or wait until the trailer opens up to find out there’s something actually wrong with the temperature within the limits. So okay, I’ll hand it back to Todd. Talk about all the other great things that the sensors and cables can provide.

9:34 | Todd Burch

Thanks. David. So yeah, at the beginning of this webinar, we talked about a poll that was live so I misunderstood how this worked. I think we want to launch some of our questions now to kind of get a response of who we have on the call. So our first question is, we want to understand what is the makeup of your fleet from a trailer refrigeration unit? Are you a Thermo King carrier? Do you have another type of unit?

Alright, we’re at a pretty good amount of folks that have responded. So we’re going to close this poll and move over to our next question. All right. Next question we have is: We know that during these macroeconomic factors, a lot of fleets are what we call opportunistic with how they purchase their refrigeration units. We’ve heard, talking to a lot of customers, people have preferences, but we’re curious to know, how well do your fleet? What is the average age of each one of your units? How familiar are you with your fleet? So here’s the next question.

Okay. We’ll close this poll and we have one more question for the attendees. And then the next question we have is: We’re kind of curious, do you have an existing reefer monitoring solution in place? Are you new to gaining visibility into your reefer fleet? I’m kind of curious about where you are and your purchasing process.

All right, thank you so much. We’re going to close this poll. It’s an interesting group that we have here. Let’s see. I want to share the results of our first poll. It seems like there’s not much of a surprise here based on the kind of solution that we have with the Thermo King integration. About 39% of you have a Thermo King.

The others have carriers. It’s kind of an even split here between carrier and a combination of Thermo King carrier. Cool. And then from our next question, let’s see what is the average age of your units? We’re seeing, I think this is something that as we’ve worked on this product, we’ve started to see that the average age of these units have slowly ticked up and I think that’s with better insights, better maintenance. As a fleet manager, y’all are able to make the life of your units last longer and be more efficient in the process and you have confidence in those issues. So cool. We’re seeing five or six years as the sweet spot here for the attendees. And then it looks like you have an existing reefer monitoring solution, it looks like most of you folks are looking to add a solution to your software stack.

Cool. Thank you so much for participating in our poll. Really appreciate it. Alright, so moving on, we think that your reefer monitoring solution, I think the core part of this is to easily manage your temperature logs. We know that the cold chain industry, temperature control, creates big business. There’s a lot at stake, more than just monetary loss.

If you don’t have a solid monitoring of your temperature, you could have hidden foodborne illnesses or your product could spoil and you wouldn’t be able to visibly see that. So where we started with our product is we knew that it was important that we built an easy log management solution through the Motive automated operations platform.

You have full log access, you can access your temperature logs at any time. It’s live. It’s continuous and then you can export these if you want to export your logs into Excel or Google Sheets or to some other analytics platform. You’re easily able to take that out. Or, if you want to present this to a customer, you can easily change the data. You can do the different kind of time cadences between 15, 30 minutes, an hour, you can include some sensors. You can remove other sensors. It really is an easy way to manage your logs and make it customizable for your business.

The next is, we knew that it was important to have a good reefer monitoring solution to help you lower your operational cost and we knew that it was more. It was important not only to be reactive … let’s say something was happening, you notice before you deployed a trailer that it wasn’t able to maintain a temperature, we knew that a reactive solution was table stakes, but getting the information to you so you can make proactive decisions is really what we aimed for when building the solution. So we think that bringing all of your reefer data into the dashboard will help you get a larger view of how your fleet is performing, help you to understand the health of your units, and help you to build a maintenance plan.

What’s the probability of a trailer performing well or maintaining temperature, helping you to decide what assets to deploy, really giving you a proactive solution to help you. In addition to this solution, our dashboard, our sensor, and our integration, we know that we’ve also built additional features like alarms — which is on the next slide — we’ve covered from a working perspective, I think they have 250 plus alarm codes.

This information, through our Thermo King integration, you’re able to pull in this information into the fleet dashboard. You’re able to check these alarms before you start your pre-cooling and we’ve heard sometimes as a fleet manager you maybe were aware of an alarm, maybe this was something that the driver would close out on there manually. We’re bringing these types of features into the Motive Fleet Dashboard, so you have full visibility into your reefer fleet … the other part … a lot of old solutions are like existing processes depends a lot on the drivers, you’re training them on how to program the refrigeration units, having a training course on how they can monitor as they’re driving. You depend a lot on the driver being very aware of how your trailer is performing with our solution.

We’ve worked extensively to give you the controls in a centralized location to help you act as a fail-safe for your drivers. Or, if you have our Thermo King integration, it allows you to centrally remotely control your refrigeration unit, set temperature, set modes, and then monitor as that trailer is moving toward a pickup or a drop-off location.

We also think that this will save you time, especially if you have the Thermo King integration with the remote control. It’ll save you time from going out to your yard to do an inspection or pre-cool. It’ll save you time and conversations with your driver. You can easily, on our fleet dashboard, look at how that unit is performing, get a sense of, is it doing well or not and then take action from the Motive Fleet Dashboard.

And then, David mentioned this earlier … when we’re talking about the products … Obviously this is a three-pronged solution here. We have the Thermo King integration, we have an Environmental Sensor that works in any type of trailer unit and then we have our dashboard which is the software side of this. And, we know it’s important not just to collect data but also to present it in a way that you can understand. You can make quick decisions, take action on that … hovering over detail, understanding what is going on in that trailer without bothering your driver or pulling out the data to manipulate any way that you want. We think this is a core way of driving real value with Reefer Monitoring … so we have the final piece, as we’ve worked to bring this product to market, we’ve tested this out, we’ve given this to a few different customers.

One of our key results that we had is with Mayer Bros which they run — next slide — so Mayer Bros, I don’t know if you guys are familiar with them or not, They are in the Northeast there, mainly a cider company. They run a lot of cider products, but in addition, they can run other products like ice cream. And, as we mentioned as a proactive solution what was happening here, Mark, the transportation manager was trying to decide which trailer to deploy to an ice cream load and before he did that, he had the Environmental Sensor installed on his trailers and he ran a test to see if the trailers could get to negative 20 for the loading temperature and if they can maintain that. And during his test, he tested a handful of his trailers to decide which trailer to deploy. He figured out which one could maintain that temperature the best and fit with his program. And so he was able to dispatch that trailer with confidence knowing that it wasn’t going to fail, that it was going to deliver and drive customer satisfaction for his customer.

Now we’re going to move into — I think this is probably something that everyone here that’s attending is really excited to see — we’re going to move into a live demo, We’re going bring David back, he’s going walk us through what our product looks like in a live demo.

23:18 | David Chao

Awesome. Great! Thanks, Todd, I’m going to hop out of this real quick and we’re going to go over to a dashboard that I already have pulled up, just showcased some of the power behind the river modeling. So this customer here has predominantly our Environmental Sensor platform. Like Todd alluded to. This works perfect if you guys have a mixed fleet or non-Thermo King and even honestly, even Thermo Kings, this works regardless of what you have, your make and model of the reefer trailer.

And so you can connect up to six per one Asset Gateway. So, you’ll see later on, there’s some of them with 31 … really depending on what type of strategy they have multi-zone, single-zone, or even depending on what they’re trying to track. We’ve had customers that are looking for low temperature as well as discharge air temperature and then return air temperatures.

They actually have three places, three separate locations. They can monitor all three different types of temperature data really, depending on the regulatory and operational needs. So, for this customer, they have predominant Environmental Sensors, but they also have a couple of trailers that run Thermo King and so well, we’ll run you through both scenarios in this level right here.

So the first thing you notice — if you guys are unfamiliar with the Motive platform — is that right off the bat, you can see we do something pretty cool. We have something called an asset vehicle drive pairing groups. So you can see the vehicle here. This vehicle here is driven by Richard and it’s pulling asset 1057 98, and it’s a reefer because it has a snowflake icon right next to it.

So if you hover over it, it tells you a quick snapshot of what that temperature is going to be. So 40 F, 71% humidity. This one’s probably pulling excited or something along those lines on the map you see right here, right, right where the green arrow is? This is Richard. He’s somewhere in Syracuse pulling this load and you can get all the information right here.

Right. You can hover over another one. This one has two sensors that there’s four lines of data. There is 58 degrees temperature, 59 degrees temperature, and then 53% humidity and 50% humidity. This one is 37.4. This one has two as well. And then this one has three because there’s three lines of data. And then this one has, sorry, this one has a Thermo King unit right here.

So you can see right here Thermo King is slightly different. You see the set point, return their discharge air coil air and then you also see the three Environmental Sensors installed here. So there’s 39 degrees and 4 degrees and 41 degrees … kind of what I was alluding to. He puts in different places to send temperatures relative to what he’s needing. Okay, so we’re just going to hop in the Environmental Sensor one real quick.

We’ll find one with two. So we’ll click on David Miller’s asset. And so right here you can hop in and you’ll get all the information just for this asset. Right? You can see the location, you can see that it’s been in motion for 52 minutes. It’s currently being pulled by this vehicle with this driver. So if you’re ever interested in-vehicle data, you can pop on over.

If you’re ever interested in David’s hours of service, you can hop on over as well. But what we’re interested in here is literally looking at the telematics, you hover over the data source. You see Environmental Sensor which for as far as a reminder is this airpods-shaped sensor that goes inside the trainer that connects to our Asset Gateway via Bluetooth.

So this one has two and if you hover over it you can see this one is 58 degrees. It tells you exactly where it’s located in the front of the trailer in this case. and this one is located in the middle of the trailer. If you have multiple zones you can zone one, zone two, zone three. We will be able to differentiate between how many different zones are and what the locations are per zone.

So the one zone right here. In zone two we’ll have a different category or different subsection named zone two. And my thought is alluding to here. You can see history right of all the location that is driven in a pool of a specific segment of that history just for your ease of use. Right? So this Environmental Sensor, this is basically a quick way to get a quick snapshot of what’s happening to that specific asset.

So we’re going to pull over real quick that Thermo King unit that we had just found earlier. You can find it right here and you look into it and see right here. The telematics here is slightly different. You can see right now it’s also in motion for an hour and 52 minutes. The drivers are unidentified at the moment, but you can have your safety manager.

If you’re looking to find who the driver is, you’ll be able to … you have to look that up. But you can see the telematics. If you hover over the information icon, you can see data sources Thermo integration as well as Environmental Sensor. You can see the set point is 35 degrees. The return air is 33.8 discharges 27.1. You have the coil temperature.

Then you also have a couple other ones like ambient air, you have mod cycle, and you have battery voltage. Now you can also have Environmental Sensors here, you see right here and this one has Environmental front, you have Environmental in the middle. You also have an Environmental Sensor in the back, right? Because you might have different zones, multi zones, you might have different needs.

For example, this one’s monitoring the front, the standpoint of the discharge air, and this was monitoring like the middle air, and this one’s going to be back here. On the bottom side, you have alarms. This is where all the fault codes for Thermo King will show up if there are any. In this case, there are no active alarms but you’ll get notified when there are alarms.

And if you want to see more, you can just view more. You see a lot of other status codes and descriptions that show up. Now if we wanted … going down the user journey to assume that there’s something wrong with this unit. Like you wanted to be in continuous instead of cycle. For example, you can configure the right-hand side of the panel. Pop open.

If you have multiple zones … in this case is a single zone reefer trailer … if you have multiple zones, zone one here, you see zone two down here, and zone three down here will be separate. So you control each one individually and you’re able to toggle this on and off. If I were to click into this, this will start turning and this will send a command to turn the reef off.

You can also change the mode, right? You can go to continuous down … sorry, cycle century or even sleep mode. You can change the set point to whatever set point you wanted to be, in this case maybe 30 maybe 40, up to you. Then you can also run a pre-trip cycle which we won’t do but that’s all from the dashboard. If you have the Thermo King integration solution you can change it just by clicking this configure button. And by clicking that same icon, it will send a signal from our website to the Asset Gateway which will then communicate with the reefer to turn it on and off or do what I command that you wanted to do. Todd also brought up another thing right? One of the most important parts is the compliance aspect of it. You can go to reports, you can pull up a reefer activity reports, see all the temperature logs that we’re talking about.

Actually, we already have one pulled up just for simplicity stakes and you can see that this one’s on the Environmental Sensor platform. It has the temperature data and humidity data from that one specific temperature Environmental Sensor. For everyone … our cadence … you can change it to 30 minutes. You can change it to 15. You can change it to start. You can always change it to 15 but you can see every 15 minutes, you can get a 15-minute rolling log of whatever that temperature was.

You also get a location and you also get to see … the cool part about this is because we store it on the server, you’re able to go in and change the date. So let’s assume that you wanted to look at a specific load that was driven from across the country on four days from the 12 to the 15 of October. You click that, you’re able to get that information right away.

So we know that some customers are some companies without a telematics solution, they have to pull that into the shop for example, a Thermo King dealership. They would take that out of circulation. Thermo King would probably charge you for a log to get pulled. In this case, you don’t have to do any of that. The reefer can be running as it is right now and we can do everything from our dashboard.

Just as an example, Thermo King would also show up the same way if you have multiple sensors. You would also just have multiple columns of sensors. And Thermo King was just this way, slightly different information including discharge their return coil temperature as an example. Okay, and another thing is just as important is the alerting section right?

We understand that most people … we don’t want to see what’s new … most people won’t be looking at the free dashboard right here, like all the time, right? We understand that things often change or break while it’s in route, and so we want to give you that peace of mind as well. So we have this whole alert system set up for multiple different aspects, but in this case, particularly for temperature.

So we have alerts that you can create for both the Environmental Sensor and for Thermo King platforms for us to monitor a specific asset or assets based off of the load that they’re pulling. So all you have to do is go to reefer temperature and you can pull a temperature alert. You select the asset or a group of assets. Just in this case, I just do all of them and then you can say what conditions would trigger this alert trigger alerts when the temperature falls outside a specific range … falls inside a range.

For example, if you’re bringing something back into range, you want to get notified of that temperature rise above, or when temperatures fall below because you’re not worried about either side, you only care about one side as opposed to both. We’re just going to choose outside of a range because I think that’s the most common in most cases. and for the specific company will say 40 to 50 is the range for normal temperatures, 45 or about five degrees of deviation either way and we will get notified if the temperature exceeds 40 or 50, so if it’s 38 or 51 for example, for let’s say five minutes, then an alert will be sent by our platform to whoever it is that you want.

So in this case you can choose Mark and you can choose everybody but Mark and Jerry … sorry, so it can be the driver, it can be the fleet manager, it can be the maintenance person. You can choose in this case who that person that you want to send that letter to and then all you have to do is save it and that will be saved within our dashboard for future use. So whenever those conditions arrive, you’ll get notified of a notification to do the next step, which is like change it. If you’re, if you’re on the booking platform, you can configure it yourself or if you’re on the Environmental Sensor platform, you just call the driver. Or, the driver already has the notification that he or she can just change it themselves.

Another thing that is specific to the Thermo King platform is we also create an alert for Thermo King alarms. So if you wanted to and get notified of specific alarms because that one reefer’s performing sub-optimally but you have to use it or you’re tracking the specific error code because of maintenance performance issues.

You can go in and select a specific asset that you’ve done in the past but you can also select all the alarms that Todd was referring to, those 250 alarms. It’s all within our database and you can check all the check alarms, you can select all the alarms. You can select whatever individual alarm that you’re looking for.

You can search for it. It’s an evaporator coil, right? See all these can choose whatever you need. You select that same idea here, choose the person that you need to be notified, in this case probably the maintenance manager, or the maintenance crew and the fleet manager, then that will also be set to alert you of any abnormal behavior in the field.

Right? So you have all of it, you have the quick, easy access from the snapshot on your free dashboard to give you peace of mind that things are operating as intended. Right here, for example, you have a really easy way to view what the trip status is of whatever load that you’re pulling along with the temperature information that you need.

You can click into this. … you can click into this just for more information again. Super easy and then you have the report section that we just showed you as well as the alerts that we just went through and right now we only have the Thermo solution available for that configure option. If you’re looking for that active monitoring, if you’re looking for the carrier equivalent of that, we are working on that.

We expect that to be readily available to fulfill that subsection of … customers who are on only the carrier platform but if you’re not looking for active monitoring, active control, the remote control that we’re just talking about, Environmental Sensors again work with both Thermo King and carriers that they are making model year agnostic. It doesn’t matter what your carrier or Thermo King model is, if it’s seven plus years, all you need is the Motive Asset Gateway, two installed and our Environment Sensors to be connected.

And so that’s just an easy way to retrofit your whole fleet without caring about what it is, what trailer or what reefer it’s being installed into. Okay. That’s a quick demo. Hopefully, that was interesting and insightful. and I’ll hand it back to Todd to wrap everything up and start answering some questions. …

36:45 | Todd Burch

Thanks, David. Hey, just a reminder there is an opportunity in the webinar for you to ask questions. We have a few more slides left and then we’re going to get to answering the questions. So if you thought of something throughout this presentation, you have a couple of minutes to put your question in there .…

Our Reefer Monitoring solution plugs right into the Motive automated operations platform, through our Reefer Monitoring hardware and sensors. We bring all of your temperature-controlled trailers online, which gives you real-time visibility into the health and status of your trailers. And this is something as an integrated approach. You can have one place for an all-in-one solution for you to manage your fleet ….

Next question is: What if this fits my needs, what if I have no more questions and I want to take it for a spin?

Well there’s a few different ways … if your Motive rep you can reach out directly or you can wait until we send you the pdf of this deck and then you can visit a link here with gomotive.com/products/reefer-monitoring-system to get more information.

Then on the next slide, we think we’re a really cool company but we also have received a few awards … the interaction and the customer experience that you have….

We’re proud to continue to expand our offering for your businesses and to make sure that you have everything you need to drive profitability, and to have a more efficient fleet. And then finally, thank you for attending this webinar.

We’re going to move over and look at the questions now, so if I can bring David back onto the call … we can get into this and get into some of these questions.

The first question we have is: When will you have a carrier, TransCold integration? The answer to this is just as we’ve developed our Thermo King offering we are in active conversations with carriers. This is something that we hope to bring to market really soon. Our goal is for next year but we are actively working with that with the carrier right now.

The next question is from Adan: Does the system show the fuel level when you hover over it? David, I know that in your presentation you showed a Thermo King unit but the fuel was left out. I don’t know if you could address this question?

39:59 | David Chao

Yeah. So by hovering over the snowflake icon, you won’t be able to get the fuel level. The only way you can get it is by clicking into the asset. I think that unit probably is an older unit so that the reefer telematics box that we’re pulling from just doesn’t supply it. But a lot of our other customers that are on the platform, for example, a cheese company out in Wisconsin has that information accurately displayed on the dashboard, but there’s no easy way.

There’s no snapshot view of it. But if that’s something that I feel like a lot of us are interested in and it’s important information, that’s something that we can definitely include in future revisions of our software platform.

40:40 | Todd Burch

Perfect. Thanks, David. We have a third question here: Just to confirm that to use the reefer monitor, you need the asset tracker on the trailer, correct?

Yes, that’s a good question. One, you need the Asset Gateway attached to your trailer. That’s a requirement, and then you get to choose whether (depending on what you need out of your Reefer Monitoring solution) you need a remote control. If you have a Thermo King trailer, we suggest you do the Thermo King integration, which is a cable. If you don’t need the remote control, you can use our Environmental Sensor which goes inside of the trailer and that can be used with any manufacturer carrier or Thermo King. So you just need the Asset Gateway and then you can choose between either a Thermo King cable or the Environmental Sensor.

Next question. All right, here’s a question … Let me see if I answered this: Is there any special extra hardware needed for the Thermo King integration or is the Motive system just a plug and play application?

I think I answered that with the extra hardware needed as the Asset Gateway. Let’s see. Well, we’ll hang on for just a few more seconds to see if there’s any more questions. All right: Can the system display current reefer conditions in the mode of Driver App or on the truck’s tablet?

42:17 | David Chao

Yeah, I’ll take that one right now. The only way we can see the reefer telematics is on our website. Through the fleet view. However we are already in the works of displaying it on the fleet app, and there has already been some discussion about what level of information ti display on the Driver App, especially if your operations allow you to have drivers have that level of detail and control. Um, but the Fleet App is something that we’re actively working on right now so that the fleet managers actively view it when they’re away from the computer ….

42:51 | Todd Burch

And then David, can you talk about the prices?

42:56 | David Chao

For sure. So, like Todd alluded to, we’ll need to Asset Gateway because that’s the one with the L. T. Connection to send to our cloud service to provide that telematics data on the dashboard. So on top of the Asset Gateway, each hardware solution retails right now at $99. This is regardless for both Environmental Sensor and Thermo King. And then the current price is $5 a month per device to enable telematics. But yeah, that’s the current setup.

43:29 | Todd Burch

Yep $99 per hardware device. $5 per device subscription fee for software. Is the Asset Gateway in the associated cabling designed for harsh environments?

Yes … if you talk to your Motive rep we can give you the specifics on which, and how harsh of environments that these things operate. But they are built for use, built for extreme temperatures, and things like that.

Thank you guys for these questions … we really appreciate all the interaction during this webinar. We’ve worked on this for a few months now or over … pretty much this past year and we really appreciate you guys took the time to attend, to ask questions.

We really think that the Reefer Monitoring solution that we’ve built is going to drive that extra visibility, the real-time visibility that you need to run an efficient business. So once again thank you so much and we’re going close the webinar.

44:51 | David Chao

There’s one more question, Todd, from Joe.

44:54 | Todd Burch

I was trying to create some time for Joe to get that last question in: How frequently are temperatures refreshed? How real-time are the current readings?

45:04 | David Chao

Yeah, I’ll take that one. So, Joe, I think the first one is between the Asset Gateway and the Bluetooth-enabled sensor, as well as the cable, honestly. The sensors … send information once every minute in terms of the data. So that’s very frequent. Once every minute you’ll get a ping between the sensor and the Asset Gateway.

Now, that’s always dependent on what the LT Connection is for your Asset Gateway. If the LTE. Is great, I’ll send that breadcrumb (what we call a breadcrumb) to our service once every minute. However, if lt is not, it’s not stable, or you’re in an area of low lT coverage, we’ll store that in our Asset Gateway. We can store three months of information or Asset Gateway, which is a lot.

But until you get good at LT connection, that’s the first time you see it paying. So the moment that you get good coverage, all the information that has been stored on the Gateway will be transferred over to our cloud server.

Same thing with an Environmental Sensor … if for any reason that connection is broken between the Environmental Sensors and the Asset Gateway. We’re able to store three months of breadcrumbs or data on our Environmental Sensor without wiping it. So the moment that repairs to the Gateway or a new Asset Gateway, just in case your asset is broken. For some reason, you do like hitting a wall or something like that. That data will still be stored and then the next time it’s active, it will send that over to the Asset Gateway, which will then beam it up to our servers.

Again, three months’ worth of data should be stored on your devices either way. The same thing Thermo King. Thermo King is a little easier because it’s cabled in. We’ll pull information once every minute. And once that again if LT coverage if it’s good we’ll send that up. If it’s not then we’ll store it there. So it should be ready to be frequent and very real time.

46:54 | Todd Burch

Perfect. If there’s not any more questions then once again thank you for attending the webinar. And if you have any questions, reach out to your Motive rep or you can wait for the pdf of this webinar in your email. Thank you.

Learn more about the Motive Reefer Monitoring system.

Request a demo to see it in action.